Synopsis

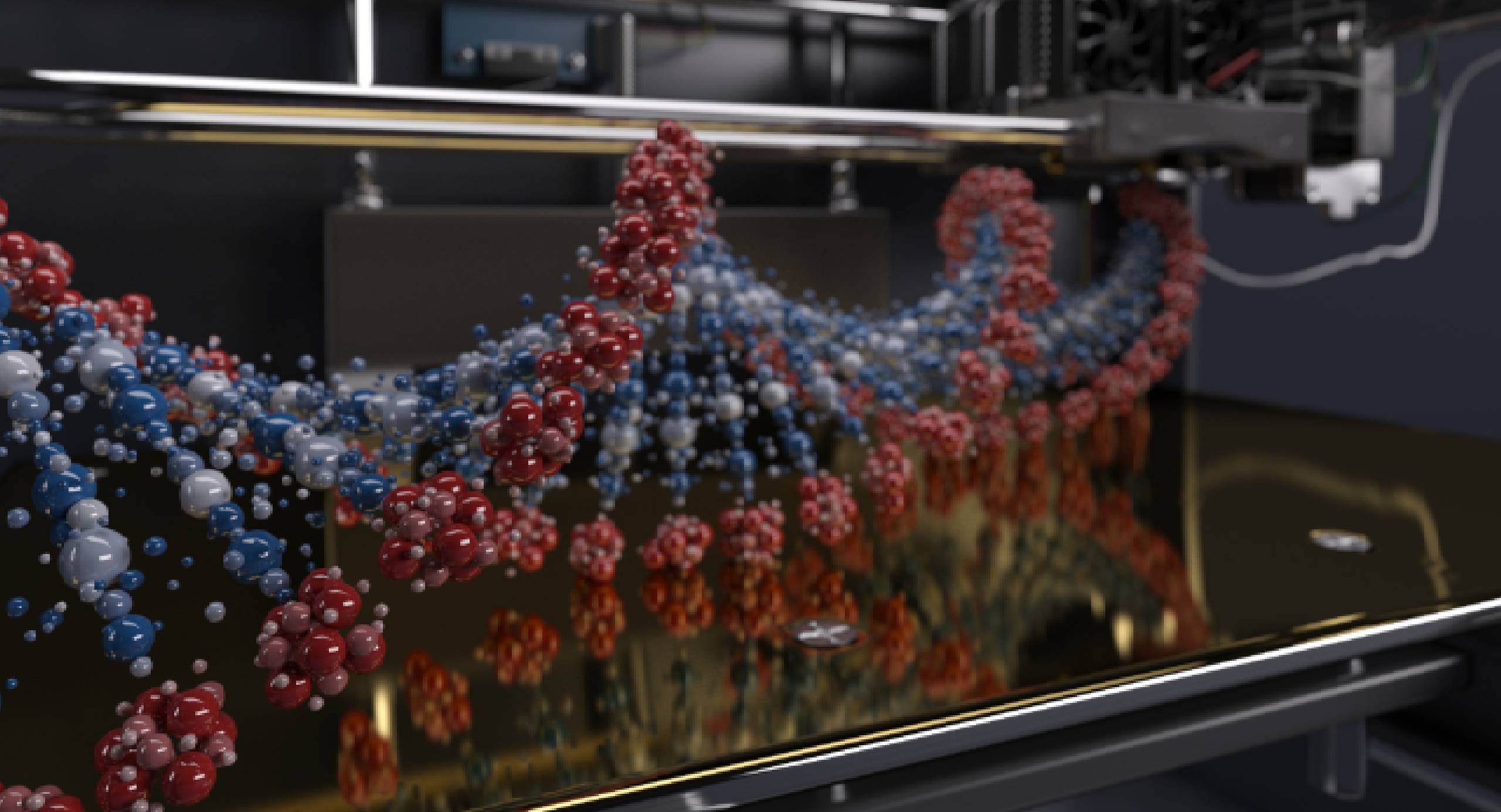

The journey from a digital concept to a tangible, functional product is often the greatest hurdle in the manufacturing cycle. Today, this process is being drastically accelerated and refined by advanced additive technologies, particularly sla 3d printing and sls 3d printing. This blog explores the distinct advantages of these two foundational processes, detailing how they are indispensable tools for high-fidelity product development and manufacturing. We will define the difference between a quick-turn conceptual model and a functional 3d prototype, outlining how to successfully implement prototype 3d printing strategies that save time and resources. Furthermore, we examine the convenience of utilizing an online 3d printing service for rapid access to these technologies, bypassing the need for immediate capital expenditure. Understanding the factors that contribute to the overall 3d printing machine price for these systems is critical for scaling operations. By choosing the right technique, whether it is the detail-oriented SLA or the robust capabilities of sls printing, manufacturers can compress their product development cycle and transition seamlessly from initial concept to final, high-performance product.

Table of Contents

-

The Foundation of High-Fidelity Prototyping

-

SLA 3D Printing: Precision and Aesthetics

-

Nylon 12 or PA2200 for SLS

-

SLS Printing: Strength and Complexity

-

Polycarbonate or Accura60 for SLA

-

Strategic Prototype 3D Printing

-

Leveraging Online 3D Printing Service Providers

-

Understanding the 3D Printing Machine Price

-

Scaling from 3D Prototype to Mass Production

-

Dynotech’s Role in Accelerating Product Development

-

Empowering Precision Manufacturing in India

The Foundation of High-Fidelity Prototyping

In the fast-paced world of product design, the speed and accuracy with which an engineer can evaluate a physical model often determine the project’s success or failure. Traditional methods like CNC machining and injection molding require expensive, time-consuming tooling just to produce a single part. This is why sla 3d printing (Stereolithography) and sls 3d printing (Selective Laser Sintering) have become the pillars of modern product development. These two technologies enable designers to quickly materialize concepts, identify flaws, and validate component function before committing to costly mass production tooling. They represent the most critical step in minimizing risk and maximizing efficiency during the vital transition from digital file to tangible, functional 3d prototype.

SLA 3D Printing: Precision and Aesthetics

Stereolithography, or sla 3d printing, is renowned for delivering the highest resolution and smoothest surface finish among all additive technologies. This process uses a UV laser to selectively cure layers of liquid photopolymer resin, creating parts with exceptional fine detail and accuracy. SLA parts are ideal for concept models, appearance prototypes, and tooling masters where aesthetics and tight dimensional tolerances are paramount. The ability to produce parts that are almost indistinguishable from injection-molded components straight out of the machine makes SLA indispensable for designers needing to present a polished, final-look 3d prototype to stakeholders or clients before mass production begins.

Nylon 12 or PA2200 for SLS

Dynotech’s SLS solutions frequently utilize Nylon 12 (or PA2200), a robust thermoplastic known for its excellent durability, flexibility, and chemical resistance. This material is paramount for sls printing of functional parts in demanding environments. Components created from Nylon 12 are often used for hinges, snap-fit assemblies, and enclosures that require high impact strength and temperature resistance. This material capability elevates the 3d prototype from a visual model to a fully functional engineering component, ready for rigorous field testing.

SLS Printing: Strength and Complexity

In contrast to SLA’s focus on surface quality, sls printing is primarily valued for its mechanical properties and geometric freedom. Selective Laser Sintering uses a laser to fuse powdered thermoplastic polymers, such as nylon, layer by layer. Because the surrounding unfused powder supports the part during the build, SLS requires no external support structures, enabling the creation of complex internal features, intricate nested parts, and highly complex lattice structures. Parts produced through sls 3d printing are known for their high strength, durability, and superior material utilization, making them the preferred choice for functional testing and even low-volume, end-use components.

Polycarbonate or Accura60 for SLA

The term 3d prototype encompasses everything from a simple concept model to a fully functional pre-production part, and the strategic use of prototype 3d printing dictates project success. A project may start with an inexpensive Fused Deposition Modeling (FDM) print for basic fit-checking, then move to SLA for detailed appearance models, and finally utilize SLS for rigorous mechanical and environmental testing. Choosing the right technology at each stage—based on cost, speed, and required functional properties—is key to efficiency. By using SLS and SLA strategically, companies avoid wasting time and budget on tooling changes that could have been identified much earlier in the product lifecycle.

Strategic Prototype 3D Printing

For advanced sla 3d printing requirements, Dynotech offers specialized resins like those based on Polycarbonate or Accura60. Polycarbonate-like materials provide excellent stiffness, high temperature resistance, and durability, bridging the gap between standard resins and engineered thermoplastics. These resins are essential for creating highly precise fixtures, clear optical components, or demanding master patterns for vacuum casting. The availability of such high-performance resins ensures that the SLA 3d prototype is not only aesthetically perfect but also capable of simulating the mechanical performance of final production polymers.

Leveraging Online 3D Printing Service Providers

For manufacturers and designers without the capital to purchase their own equipment, utilizing an online 3d printing service is the most efficient gateway to these technologies. These service providers maintain fleets of industrial-grade sla 3d printing and sls 3d printing machines, allowing clients to simply upload a CAD file and receive a finished part within days. This model bypasses the need for large capital expenditure, internal maintenance teams, and extensive operator training, making cutting-edge additive manufacturing accessible on a per-project basis. It’s an invaluable resource for rapid market testing and for businesses that only require periodic access to high-end sls printing capabilities.

Understanding the 3D Printing Machine Price

For those planning to integrate these technologies in-house, understanding the investment details is paramount. The 3d printing machine price for industrial-grade SLA and SLS systems reflects the complexity of the technology, the size of the build chamber, and the sophistication of the laser and material handling systems. SLS machines, in particular, require complex thermal management and inert gas controls, contributing to a higher price than basic SLA machines. However, the investment is recouped through high utilization, the reduced cost of materials (powder can often be recycled), and the ability to produce functional, end-use parts without any external tooling costs.

Scaling from 3D Prototype to Mass Production

The successful implementation of prototype 3d printing technology allows for a seamless transition to scalable manufacturing. The data gathered from testing a high-fidelity 3d prototype created via sls printing is directly transferable to tooling adjustments for injection molding. Furthermore, as the costs of the machines decrease and production speed increases, low-volume sls 3d printing is increasingly becoming an economically viable alternative to tooling for niche parts or serialized components, truly blurring the line between prototyping and final production.

Dynotech’s Role in Accelerating Product Development

Dynotech Instruments Pvt. Ltd. specializes in bringing world-class Additive Manufacturing technology to Indian industry, offering comprehensive solutions for both sla 3d printing and sls 3d printing. We represent global leaders in AM, ensuring our clients receive access to the most reliable, high-resolution machinery and the latest engineering-grade materials, including specialized polyamides and resins.

Empowering Precision Manufacturing in India

We provide the necessary technical expertise, supporting companies from the initial concept stage to full-scale deployment, whether they require a specific 3d prototype or a strategic investment to reduce the 3d printing machine price over the long term. Dynotech empowers Indian manufacturers to master prototype 3d printing, accelerating innovation and maintaining a competitive edge in global product development.

FAQs

What are the key differences in part properties between SLA 3D printing and SLS 3D printing?

The primary difference lies in the material and resulting properties. sla 3d printing uses liquid photopolymer resins cured by a UV laser, resulting in parts with extremely smooth surfaces, high feature resolution, and high aesthetic quality, ideal for visual and appearance prototypes. sls 3d printing uses thermoplastic powder, typically nylon, fused by a CO2 laser, yielding parts with high mechanical strength, durability, chemical resistance, and excellent suitability for functional testing. Therefore, the choice depends on whether the 3d prototype needs visual appeal (SLA) or mechanical performance (SLS).

How can an online 3d printing service assist companies in their prototype 3d printing strategy?

An online 3d printing service assists companies by providing on-demand access to industrial-grade sls printing and SLA equipment without the massive capital outlay of purchasing a machine. This allows businesses to rapidly test designs, validate material choices, and produce a high-fidelity 3d prototype quickly, regardless of their in-house manufacturing capabilities. This model is particularly beneficial for small design firms or large corporations needing sporadic access to advanced materials, as it enables faster iteration and reduces time-to-market without requiring a major increase in the internal 3d printing machine price budget.

How does the process of SLS printing achieve superior part strength and complex internal geometries?

sls printing achieves superior part strength and complexity by using a powder bed fusion process. Because the unfused powder surrounding the part acts as a natural, sacrificial support structure, parts can be designed with complex internal channels, intricate lattices, and completely nested assemblies without the need for external supports. The high strength comes from the use of engineering-grade thermoplastics like nylon and the high thermal management of the build chamber, which ensures a dense, homogenous fusion, making the resulting 3d prototype suitable for rigorous functional testing.

What are the key factors determining the final 3d printing machine price for industrial SLA and SLS systems?

The 3d printing machine price for industrial systems is determined by the size of the build volume, the laser configuration (single versus multi-laser for speed), and the complexity of the material handling system. SLS systems generally have a higher starting price than SLA due to the need for expensive thermal management, inert gas (nitrogen) controls, and sophisticated powder recycling mechanisms required for successful sls 3d printing. For any system, the cost of post-processing equipment (curing, depowdering, sieving stations) and the necessary service contract must be factored into the final investment calculation.

What is the difference between a conceptual model and a functional 3d prototype, and which technology is best for each?

A conceptual model is primarily used for visualization, fit-checking, and aesthetic review—it prioritizes surface finish and detail. This is best achieved using sla 3d printing. A functional 3d prototype, however, is designed to simulate the mechanical performance and environmental resistance of the final product and is subjected to rigorous testing. This type of prototype is best produced using sls printing, which utilizes strong, engineered thermoplastics like nylon to ensure the physical properties of the printed part accurately reflect the final production component’s behavior under stress.