Synopsis

The rigid confines of traditional subtractive manufacturing are rapidly being redefined by the possibilities of Additive Manufacturing (AM). At the cutting edge of this shift is industrial 3d printing, specifically the technology dedicated to working with high-performance metals. This blog serves as an essential guide to the technology empowering the next generation of aerospace, medical, and tooling component design. We will focus intensely on the robust capabilities of the metallic 3d printing process, detailing how a metal printing machine works to build complex parts layer-by-layer from fine metal powders. Crucially, we will dissect the widely adopted 3d printing dmls (Direct Metal Laser Sintering/Melting) process, which uses powerful lasers for the highest quality and density. Understanding how this laser-based fusion, often referred to as metal laser printing, unlocks geometric freedom is key to competitive advantage. Furthermore, we explore the technology significantly accelerates the product development cycle, enabling true rapid prototyping 3d printing and drastically reducing lead times. Finally, we examine the sophisticated engineering that goes into every modern metal 3d printing machine, ensuring manufacturers can make an informed choice for their high-performance application needs.

Table of Contents

-

The New Paradigm in Manufacturing

-

The Mechanism of Metal Laser Printing

-

The Power of DMLS and SLM Technology

-

From Concept to Component- Rapid Prototyping 3D Printing

-

Overcoming Traditional Design Constraints

-

Scaling Up- The Economic Case for Industrial 3D Printing

-

Future Trends and Material Science

-

The Strategic Value Proposition

-

Dynotech’s Role in Additive Manufacturing

-

Driving India’s Manufacturing Future

-

Wide Power Range (3KW to 60KW)

-

Identifying & Analysing the existing problems

The New Paradigm in Manufacturing

For decades, the creation of metal components was governed by the limitations of subtractive processes—machining away material from a solid block or using rigid molds. However, the requirement for lighter, stronger, and more geometrically complex parts has necessitated a fundamental change in production philosophy. This paradigm shift is centered around industrial 3d printing, which builds objects layer-by-layer, allowing for internal lattice structures and organic shapes impossible to achieve via casting or milling. This transition is not merely about novelty; it represents a critical pathway to mass customization, supply chain resilience, and significant material waste reduction, making the metallic 3d printing sector one of the fastest-growing segments in advanced manufacturing globally.

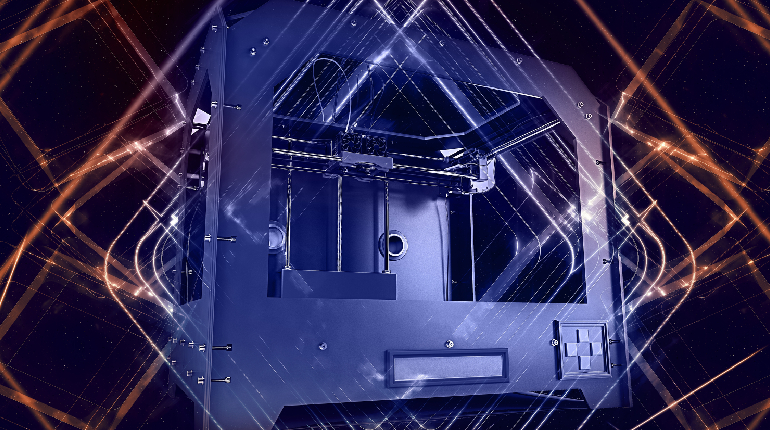

The Mechanism of Metal Laser Printing

At the core of this revolution is the specialized metal printing machine, which uses high-powered lasers and inert atmospheres to fuse metal powders. This process, often broadly termed metal laser printing, involves spreading a fine layer of metal powder across a build plate, followed by a focused laser beam selectively melting or sintering the powder according to the digital CAD file. The build plate then drops incrementally, and the process is repeated until the part is complete. The control and precision required for this fusion are immense, as the resulting components must possess mechanical properties—such as density, strength, and fatigue resistance—that are comparable to or exceed those of wrought or cast materials. The high energy density and controlled environment are key to ensuring metallurgical quality.

The Power of DMLS and SLM Technology

The two most prevalent processes in this field are Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM), often referred to under the umbrella of 3d printing dmls. While functionally similar, SLM utilizes the laser’s intense heat to fully melt the metal powder, resulting in components with exceptionally high density and uniform properties, ideal for critical load-bearing parts. DMLS, or similar processes, can involve partial sintering, which is sometimes used for more porous structures like bone implants. The capabilities of the metal 3d printing machine are therefore defined by its ability to achieve full fusion, delivering near-net-shape components with high geometric accuracy and structural integrity necessary for demanding applications.

From Concept to Component- Rapid Prototyping 3D Printing

One of the most immediate and impactful benefits of adopting this technology is the dramatic acceleration of product development cycles. Traditional prototyping involved expensive tooling and lengthy lead times for casting or machining parts, often taking weeks or months to get a single iteration. With rapid prototyping 3d printing capabilities, manufacturers can now produce functional metal parts—not just plastic facsimiles—in a matter of days. This ability to quickly test and iterate designs dramatically reduces the time-to-market for new products, allowing companies to innovate faster and respond to competitive pressures more effectively. This agility is a defining characteristic of best-in-class, forward-thinking manufacturing operations across all industries.

Overcoming Traditional Design Constraints

The greatest value proposition of metallic 3d printing lies in its capacity to create geometries that are simply impossible using traditional manufacturing constraints. This includes complex internal cooling channels, weight-saving lattice structures, and consolidated assemblies that merge multiple parts into a single component. This design freedom, often termed “Design for Additive Manufacturing” (DFAM), allows engineers to optimize parts for performance rather than manufacturability. By reducing part count and integrating functionality, manufacturers cut down on assembly time, minimize potential points of failure, and often achieve significant weight reduction, which is vital for electric vehicle efficiency and aircraft fuel economy.

Scaling Up- The Economic Case for Industrial 3D Printing

For manufacturers considering the move to AM, assessing the economic case for industrial 3d printing involves analyzing more than just the machine cost. While the cost per part may be higher than mass-produced cast components, the savings generated by eliminating tooling costs, reducing inventory, and accelerating product development often deliver a superior return on investment. Furthermore, the ability to produce on-demand spare parts minimizes supply chain risks. As the technology matures, and the speed and efficiency of the metal 3d printing machine systems improve, the economic viability of additive manufacturing continues to expand beyond just low-volume, high-value components.

Future Trends and Material Science

The future of metal laser printing is closely tied to advancements in material science, with continuous development focused on new alloys and improved powder quality. Research is pushing the boundaries of what a 3d printing dmls machine can process, moving from common stainless steels and aluminums to high-performance refractory metals and advanced ceramics. As these material options expand and the printing speeds increase through the use of multi-laser systems, the range of applications for the metal printing machine will only broaden, further solidifying its position as a core technology in any advanced manufacturing ecosystem, supporting global trends in complex part fabrication.

The Strategic Value Proposition

The profound ability of metal AM to reduce time-to-market and enable lightweight, high-performance parts secures its essential role in modern production. The capability to consolidate assemblies and customize components ensures that metallic 3d printing offers not just an alternative method, but a superior manufacturing paradigm for sectors demanding the highest levels of quality and efficiency.

Dynotech’s Role in Additive Manufacturing

Dynotech Instruments Pvt. Ltd. is committed to bringing the leading edge of Additive Manufacturing technology to Indian industry, exclusively representing global innovators like Aconity 3D. We provide the crucial access and expertise necessary to successfully implement industrial 3d printing solutions, including cutting-edge metal 3d printing machine systems built on modular, customizable platforms.

Driving India’s Manufacturing Future

Our commitment is to be the partner that helps Indian manufacturers integrate complex metallic 3d printing and rapid prototyping 3d printing capabilities. By supplying this innovative technology and offering deep process know-how, Dynotech ensures that local companies can accelerate their design cycles, drastically reduce manufacturing lead times, and produce world-class components that meet the highest global standards for quality and complexity.

Customization via Modular Platform

Dynotech, in partnership with Aconity 3D, offers industrial 3d printing solutions built on a highly modular platform. This unique architecture allows users to easily modify and tailor their metal printing machine systems to specific production needs—whether that involves changing the laser power, adding external powder handling, or optimizing the chamber for specific materials like refractory metals. This modularity ensures that the initial investment remains relevant and adaptable to future material developments or changing production demands, offering a tailor-made additive manufacturing solution that can evolve with the business.

Selective Laser Melting (SLM)

Selective Laser Melting (SLM) is a highly precise powder bed fusion technique employed by advanced metal 3d printing machine systems to create fully dense metal parts. In this process, the focused laser beam brings the metal powder to a complete molten state, resulting in a homogenous, solid component with virtually no porosity. This full melting capability is critical for applications requiring high structural integrity, such as aerospace load-bearing parts, medical implants, and tooling inserts exposed to high stress, ensuring the mechanical performance is guaranteed and certified.

FAQs

What is the key advantage of using metallic 3d printing over traditional methods like casting or machining?

The key advantage of metallic 3d printing is the unprecedented freedom in design and geometry that it offers engineers. Unlike casting or machining, which are constrained by tooling or cutting paths, additive manufacturing allows for the creation of components with complex internal features, such as intricate lattice structures and conformal cooling channels. This enables part consolidation, where multiple traditional parts are merged into a single component, reducing assembly time and minimizing failure points. Furthermore, the technology significantly accelerates the product development process, facilitating true rapid prototyping 3d printing and dramatically cutting time-to-market.

How does a metal printing machine using DMLS technology work to create fully functional components?

A metal printing machine utilizing 3d printing dmls technology operates on the principle of powder bed fusion. The machine first spreads a very thin, precise layer of metal powder across a build platform. A high-powered laser then selectively traces the cross-section of the part, heating and fusing (sintering or fully melting) the powder particles together. The platform then drops incrementally, and the process is repeated until the part is complete. This layer-by-layer fusion, often referred to as metal laser printing, continues until the complex component is fully built, achieving near-net shape with high density and mechanical integrity.

How does industrial 3d printing contribute to reducing supply chain risks and increasing production flexibility?

industrial 3d printing significantly reduces supply chain risks by allowing manufacturers to produce high-value, functional components locally and on-demand, eliminating reliance on lengthy international lead times for specialized parts. Instead of warehousing large inventories of spare parts, companies can store digital files and print the component when needed. This digital inventory model, powered by a reliable metal 3d printing machine, provides unparalleled production flexibility, allowing manufacturers to quickly pivot to custom orders or address critical equipment failures without major operational delays.

What is Selective Laser Melting (SLM) and why is it crucial in the metal laser printing field?

Selective Laser Melting (SLM) is a form of metal laser printing that uses a laser to bring the metal powder to a complete molten state, resulting in a denser, less porous final component compared to some sintering processes. This full melting capability is crucial because it delivers high structural integrity, which is necessary for aerospace load-bearing parts and high-stress medical implants. The high quality and density achieved by SLM are defining factors in selecting a metal printing machine for applications requiring guaranteed mechanical performance and minimal post-processing.

What factors should be considered when evaluating the investment in a new industrial 3d printing machine?

When evaluating the investment in a new industrial 3d printing machine, potential buyers must look beyond the initial cost to assess the machine’s material compatibility (what range of metal powders it can process), the size of its build volume, and the laser configuration (single or multi-laser). Crucially, the quality and reliability of the metal 3d printing machine are paramount, as the component’s mechanical integrity depends on the precision of the build process. Buyers should also prioritize supplier support for process optimization and training, ensuring they can effectively utilize the complex capabilities for successful production runs.