Synopsis

The manufacturing industry is witnessing a powerful convergence where additive and subtractive technologies are no longer viewed as rivals, but as a single, unified force. This blog explores the concept of hybrid manufacturing, a strategic approach that combines the design freedom of 3D printing with the high precision of CNC machining. We analyze how this integration allows for the rapid creation of “near-net” shapes that are subsequently refined to micron-level tolerances. We detail the benefits of this synergy, including reduced material waste, significantly shorter lead times, and the ability to produce parts with complex internal geometries that are still production-ready. By examining the transition from digital concept to finished industrial component, we demonstrate how Dynotech’s expertise helps manufacturers optimize their workflow. Discover how “1 + 1 = 3” in the world of hybrid production, delivering superior part performance for the Aerospace, Automotive, and Tooling sectors.

Table of Contents

-

Beyond the Binary: The Rise of Hybrid Production

-

The Additive Advantage: Creating Near-Net Shapes

-

The Subtractive Finish: Precision Where It Matters

-

Strategic Benefits of Technology Integration

-

Drastic Reduction in Material Waste and Scrap

-

Speed to Market: Eliminating Multiple Setups

-

Design for Performance: Internal Channels and Lattices

-

High-Value Repairs: Rebuilding Worn Components

-

Why Dynotech? Orchestrating the Hybrid Workflow

Beyond the Binary: The Rise of Hybrid Production

For years, engineers had to choose between the geometric complexity of 3D printing and the surface integrity of CNC machining. Beyond the Binary: The Rise of Hybrid Production Today, that choice is obsolete. Hybrid manufacturing merges these two processes into a cohesive workflow, allowing industries to exploit the strengths of both while mitigating their individual weaknesses.

The Additive Advantage: Creating Near-Net Shapes

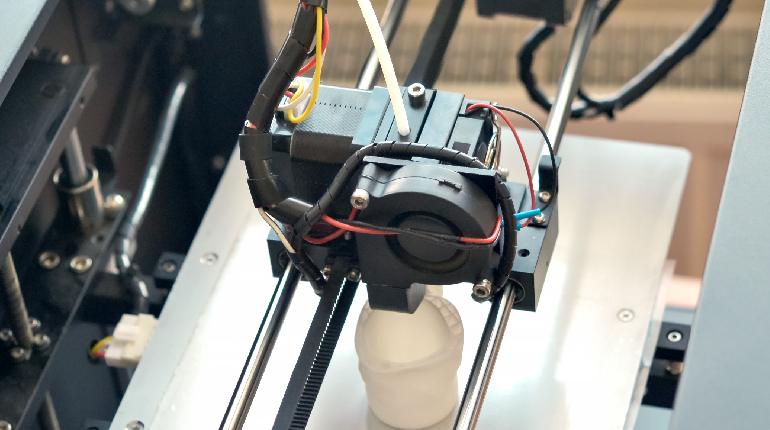

The process typically begins with Directed Energy Deposition (DED) or Powder Bed Fusion. The Additive Advantage: Creating Near-Net Shapes Using additive technology, the part is built “layer-by-layer” into a near-net shape, incorporating complex internal cooling channels or lightweight lattice structures that are impossible to mill.

The Subtractive Finish: Precision Where It Matters

The Subtractive Finish: Precision Where It Matters Once the core geometry is established, CNC machining takes over. Subtractive tools refine critical features such as bearing seats, threads, and sealing faces to production-grade tolerances (often up to 0.1 nm) and high surface finishes that 3D printers alone cannot achieve.

Strategic Benefits of Technology Integration

Strategic Benefits of Technology Integration provide a massive competitive advantage.

Drastic Reduction in Material Waste and Scrap

Drastic Reduction in Material Waste and Scrap Conventional CNC often starts with a large, expensive billet and removes up to 90% of the material as chips. In a hybrid setup, you only add the material you need, reducing waste by as much as 70%—a critical factor when working with high-value alloys like Titanium or Inconel.

Speed to Market: Eliminating Multiple Setups

Speed to Market: Eliminating Multiple Setups By printing and machining in a single system or a streamlined sequence, manufacturers eliminate the need for multiple handovers, re-fixturing, and alignment checks, cutting production cycles by 40% or more.

Design for Performance: Internal Channels and Lattices

Design for Performance: Internal Channels and Lattices is where hybrid manufacturing truly shines. Additive processes can create “un-makeable” internal geometries, such as conformal cooling channels in injection molds. CNC then ensures that the mating surfaces and fluid interfaces are perfectly smooth and accurate.

High-Value Repairs: Rebuilding Worn Components

High-Value Repairs: Rebuilding Worn Components Hybrid systems offer a unique “repair” capability where worn sections of turbine blades or industrial tools can be rebuilt via additive deposition and then re-machined to their original specifications, extending the lifespan of critical machinery.

Why Dynotech? Orchestrating the Hybrid Workflow

Why Dynotech? Orchestrating the Hybrid Workflow With 30+ years of experience, Dynotech is the partner of choice for Indian manufacturers looking to bridge the gap between additive and subtractive worlds. We help you navigate the complexities of process planning and material compatibility, ensuring your hybrid manufacturing strategy delivers 100% innovative technology results. By choosing a hybrid approach, you aren’t just making a part; you are optimizing the entire lifecycle of industrial production.

FAQs

What is hybrid manufacturing?

Hybrid manufacturing is the integration of additive manufacturing (3D printing) and subtractive manufacturing (CNC machining) into a single process chain. It uses 3D printing to create complex, near-net shapes and CNC machining to achieve high precision and superior surface finishes on critical features.

Why not just use 3D printing for the whole part?

While 3D printing excels at complex shapes, it often lacks the dimensional accuracy (tolerances) and smooth surface quality required for functional mechanical interfaces like threads, bearing seats, or sealing faces. CNC machining is required to bring these specific features up to production standards.

Does hybrid manufacturing save money on raw materials?

Yes, significantly. Traditional CNC machining is subtractive, meaning you buy a large block of metal and “waste” most of it. Hybrid manufacturing only adds the metal needed for the part, reducing material consumption by up to 65-70%, which is a huge saving for expensive materials like nickel alloys.

Can I use hybrid manufacturing to repair existing parts?

Absolutely. One of the standout benefits is the ability to add material directly onto a worn or damaged part (like a turbine blade or a mold) and then machine it back to its original dimensions. This is much more cost-effective than replacing the entire component.

Which industries benefit the most from a hybrid approach?

The Aerospace, Medical, Automotive, and Tooling industries are leading the way. These sectors require parts that are lightweight and geometrically complex (additive) but also demand extreme precision and reliable mechanical performance (subtractive).