Synopsis

For decades, the mantra of engineering has been “Design for Manufacturing” (DFM), with a heavy focus on the constraints of drills, lathes, and milling bits. However, the rise of industrial 3D printing requires a radical shift in mindset: Design for Additive Manufacturing (DfAM). This blog explores why engineers must “unlearn” traditional subtractive logic to fully exploit the capabilities of metal and polymer 3D printing. We examine the core principles of DfAM, including topology optimization, lattice structures, and part consolidation. By contrasting the “subtractive mindset” (where complexity costs money) with the “additive mindset” (where complexity is free), we demonstrate how manufacturers can achieve unprecedented weight reduction and functional integration. Discover how Dynotech’s expertise in additive solutions helps Indian engineers transition from restricted, blocky designs to high-performance, organic geometries that redefine what is possible in the Aerospace, Medical, and Automotive sectors.

Table of Contents

-

The Mental Shift: From Subtractive to Additive

-

Why Traditional DFM Rules No Longer Apply

-

Complexity is Free: Embracing Geometric Freedom

-

Core Principles of DfAM

-

Topology Optimization: Letting Math Design the Part

-

Lattice Structures: Achieving Strength Without the Weight

-

Part Consolidation: Turning Assemblies into Units

-

Case Study: Reducing Weight and Assembly Time

-

Overcoming the Learning Curve: Managing Support and Orientation

-

Why Dynotech? Bridging the Knowledge Gap in DfAM

The Mental Shift: From Subtractive to Additive

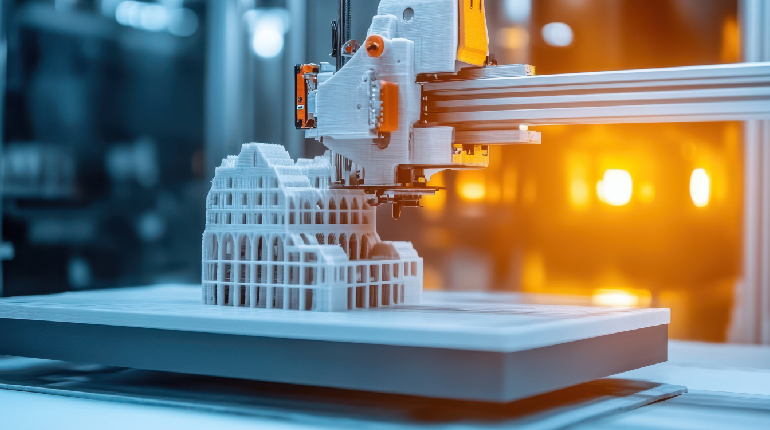

Traditional machining is a battle against physics and tool accessibility. If a drill can’t reach it, you can’t make it. The Mental Shift: From Subtractive to Additive This reality has forced engineers to design parts that are primarily composed of blocks, cylinders, and flat planes. Design for Additive Manufacturing (DfAM) shatters these constraints. Because 3D printing builds parts layer-by-layer from the ground up, the “un-machinable” becomes standard. To succeed, however, engineers must unlearn the habit of designing for the tool and start designing for the function.

Why Traditional DFM Rules No Longer Apply

Why Traditional DFM Rules No Longer Apply In CNC machining, every extra pocket, hole, or curve adds machine time and cost.

Complexity is Free: Embracing Geometric Freedom

Complexity is Free: Embracing Geometric Freedom In the additive world, it takes the same amount of time to print a solid block as it does to print a complex, organic bracket of the same volume. In fact, complex parts are often cheaper to print because they use less material. This “complexity for free” axiom allows for the creation of conformal cooling channels and internal voids that were previously impossible.

Core Principles of DfAM

Core Principles of DfAM are the tools of this new revolution.

Topology Optimization: Letting Math Design the Part

Topology Optimization: Letting Math Design the Part Instead of a designer drawing a shape, they define the loads and constraints. Software algorithms then determine where material is strictly necessary, resulting in organic, “bone-like” structures that are significantly lighter yet just as strong as their bulky predecessors.

Lattice Structures: Achieving Strength Without the Weight

Lattice Structures: Achieving Strength Without the Weight By replacing solid internal sections with microscopic lattice grids, engineers can achieve high stiffness-to-weight ratios and enhanced shock absorption, which is critical for Medical implants and Aerospace components.

Part Consolidation: Turning Assemblies into Units

Part Consolidation: Turning Assemblies into Units is perhaps the most powerful advantage of DfAM.

Case Study: Reducing Weight and Assembly Time

Case Study: Reducing Weight and Assembly Time Consider a traditional hydraulic manifold made of 20 separate parts, gaskets, and fasteners. With DfAM, this can be printed as a single, unified component. This not only reduces weight by eliminating heavy fasteners but also removes potential leak points and drastically cuts assembly and inventory costs.

Overcoming the Learning Curve: Managing Support and Orientation

Overcoming the Learning Curve: Managing Support and Orientation While additive offers freedom, it has its own “magic blocks” rules. Engineers must consider part orientation to ensure structural integrity and design “self-supporting” angles to minimize the need for sacrificial support structures. Understanding these nuances is the difference between a failed print and a revolutionary product.

Why Dynotech? Bridging the Knowledge Gap in DfAM

Why Dynotech? Bridging the Knowledge Gap in DfAM With 30+ years of experience, Dynotech is more than a technology provider; we are an educational partner. We help Indian engineering teams “unlearn” the limitations of the past and master the DfAM principles of the future. By partnering with us, you gain access to the 100% innovative technology and design expertise needed to turn complex concepts into high-performance, production-ready reality.

FAQs

What does "complexity is free" mean in 3D printing?

In traditional manufacturing, adding complex features like internal holes or organic curves increases the cost of tooling and machining time. In 3D printing, the cost is based on the volume of material and build time; a complex, hollow part often uses less material and is therefore cheaper and faster to produce than a solid one.

How does topology optimization improve part performance?

Topology optimization uses mathematical algorithms to remove material from areas that do not carry significant loads. The result is a part that is much lighter but maintains the required structural stiffness, which is essential for reducing fuel consumption in Aerospace and Automotive applications.

What is part consolidation?

Part consolidation is the process of redesigning an assembly of multiple parts into a single 3D printed component. By eliminating the need for fasteners, seals, and assembly labor, you reduce the weight of the system and remove potential points of failure like leaks or loose screws.

Do I still need to worry about "support structures" in DfAM?

Yes. While 3D printing offers great freedom, you still have to consider gravity. Features with steep overhangs (typically over 45 degrees) require support structures during the build. Smart DfAM involves designing “self-supporting” geometries to minimize the need for these supports, saving time and material.

Can any engineer learn DfAM, or do I need special software?

Any engineer can learn the principles of DfAM, but specialized software (like nTop, Altair, or Autodesk Fusion) is required to perform advanced tasks like topology optimization and lattice generation. Dynotech provides the training and support to help your team transition to these advanced design workflows.