Synopsis

The fourth industrial revolution is redefining the factory floor, moving from isolated machinery toward a fully interconnected, intelligent ecosystem. This blog explores the integration of advanced laser systems into Industry 4.0 workflows, specifically focusing on the transition toward “lights-out” manufacturing. We examine how laser technology, with its digital-first DNA, serves as the ideal tool for autonomous production lines that operate 24/7 with minimal human intervention. We detail the technical role of IoT-enabled sensors, real-time data analytics, and AI-driven predictive maintenance in ensuring process stability. From automated loading/unloading to dynamic parameter adjustment via cloud connectivity, discover how Dynotech empowers Indian manufacturers to build self-optimizing “dark factories.” By merging high-precision laser cutting, welding, and marking with smart automation, we demonstrate how to achieve unparalleled OEE (Overall Equipment Effectiveness) and a future-ready competitive edge.

Table of Contents

-

The Digital Pulse of the Smart Factory

-

Laser Technology: The DNA of Industry 4.0

-

Defining “Lights-Out” Manufacturing

-

The Pillars of an Autonomous Laser Production Line

-

IoT Connectivity: Real-Time Machine-to-Machine (M2M) Talk

-

Predictive Maintenance: Eliminating Unplanned Downtime

-

Achieving “Lights-Out” with Robotic Integration

-

Automated Material Handling and Sorting

-

Dynamic Data: Processing “Lot Size One” Economically

-

Why Dynotech? Architecting Your 24/7 Autonomous Future

The Digital Pulse of the Smart Factory

The “factory of the future” is no longer a distant concept; it is a digital reality where machines communicate, diagnose, and optimize themselves. The Digital Pulse of the Smart Factory At the center of this transformation is Industry 4.0, an ecosystem where physical hardware and digital systems are linked via the Internet of Things (IoT). For manufacturers in India, the ultimate goal of this evolution is “lights-out” manufacturing—the ability to run a facility 24/7 with zero human presence on the shop floor.

Laser Technology: The DNA of Industry 4.0

Laser Technology: The DNA of Industry 4.0 Unlike mechanical tools that depend on physical templates, laser systems are digital by design. They are controlled numerically and can switch between tasks instantly based on a new data set.

Defining "Lights-Out" Manufacturing

Defining “Lights-Out” Manufacturing “Lights-out” refers to the capability of a factory to operate autonomously, often in the dark and without climate control, because the robotic and laser systems do not require the environmental comforts of human operators. This shift results in a massive leap in productivity and a significant reduction in operational overhead.

The Pillars of an Autonomous Laser Production Line

The Pillars of an Autonomous Laser Production Line are built on connectivity and intelligence.

IoT Connectivity: Real-Time Machine-to-Machine (M2M) Talk

IoT Connectivity: Real-Time Machine-to-Machine (M2M) Talk In a Dynotech-integrated facility, the laser cutter “talks” to the loading robot and the ERP system. If a part is finished, the system automatically triggers the next material load.

Predictive Maintenance: Eliminating Unplanned Downtime

Predictive Maintenance: Eliminating Unplanned Downtime Using high-frequency data adapters, our systems monitor over 1,000 data points per second. AI algorithms analyze these patterns to predict tool wear or component failure up to 40 minutes before it happens, allowing for scheduled maintenance instead of costly emergency stops.

Achieving "Lights-Out" with Robotic Integration

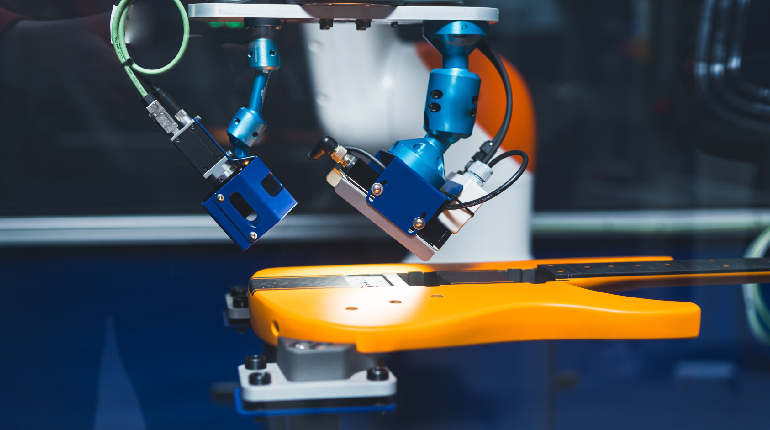

Achieving “Lights-Out” with Robotic Integration requires a seamless flow of materials.

Automated Material Handling and Sorting

Automated Material Handling and Sorting By pairing fiber lasers with robotic arms and automated warehouses, the entire cycle—from raw sheet to sorted, marked, and finished part—is completed without a single human touch.

Dynamic Data: Processing "Lot Size One" Economically

Dynamic Data: Processing “Lot Size One” Economically Industry 4.0 enables “mass customization.” A smart laser system can receive a custom order from a customer portal and adjust its cutting path and marking data on the fly, making it just as profitable to produce one unique part as it is to produce a thousand.

Why Dynotech? Architecting Your 24/7 Autonomous Future

Why Dynotech? Architecting Your 24/7 Autonomous Future With 30+ years of experience, Dynotech is not just a machine supplier; we are your Industry 4.0 architect. We specialize in integrating modular laser heads, smart sensors, and automation software into a unified, high-performance ecosystem. By choosing Dynotech, you are investing in 100% innovative technology that turns your manufacturing challenges into an autonomous, self-sustaining competitive advantage.

FAQs

What is "lights-out" manufacturing?

“Lights-out” manufacturing is a production methodology where a factory is fully automated and requires no human presence on-site. The facility can operate 24/7, even without lighting, heating, or cooling, as the robotic and laser systems operate autonomously through digital commands.

How does Industry 4.0 benefit laser cutting and welding?

Industry 4.0 integrates IoT and data analytics into laser systems. This allows for real-time monitoring of machine health, automated material handling, and the ability to change production parameters instantly via software, leading to higher precision and lower waste.

What is predictive maintenance in a smart factory?

Predictive maintenance uses AI and sensors to monitor machine performance in real-time. By identifying patterns that precede a breakdown (such as unusual vibrations or temperature spikes), the system can alert operators to perform maintenance before a failure occurs, preventing unplanned downtime.

Is "lights-out" manufacturing suitable for small batches?

Yes. One of the greatest advantages of Industry 4.0 is “mass customization.” Because laser systems are software-driven, they can switch between different designs and materials instantly, making it economically viable to produce small, custom batches (even a “lot size of one”) autonomously.

Can existing laser machines be upgraded to Industry 4.0 standards?

In many cases, yes. By adding IoT sensors, high-frequency data adapters, and smart software interfaces, older laser systems can be integrated into a connected factory network. Dynotech specializes in these custom integrations to future-proof your existing assets.