Overview

Laser head-cutting technology has come a long way ever since the automotive industry started using it in its manufacturing processes. In 1973, a laser welding system was deployed for the assembly line of a renowned company. In the 80s, laser beams began to be used massively for welding engine components and gear parts. Similarly, the 90s witnessed laser applications such as hydroformed parts and tailor-welded blanks.

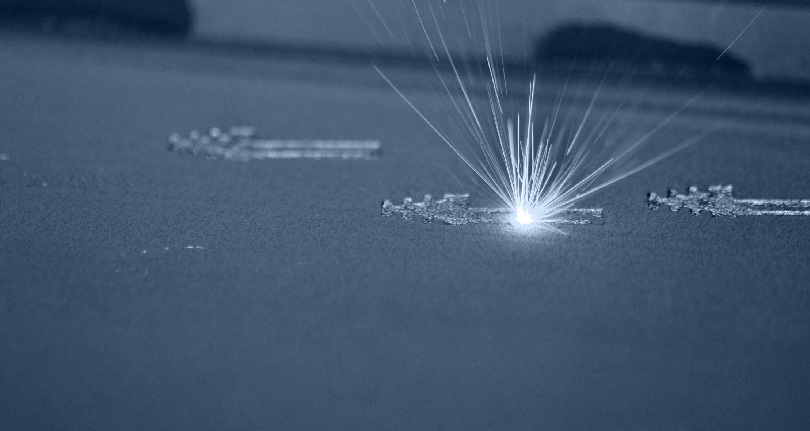

Since then, lasers have been adopted by the automotive industry for a wide range of operations apart from welding. Basic laser applications include drilling and cutting, texturing and cleaning for surface operations, marking for traceability, and scanning for inspection.

This year, lasers are deployed at literally each stage of the automobile manufacturing process, be it development and design or final assembling. For instance, they are currently using more than 800 high-power lasers in its global assembly plants.

This technology provides relevant advantages for modern automobile manufacturers, which we will discuss below in this article.

Advantages Of Laser Technology For Modern Automobile Manufacturers

- Quick Changeovers

Automobile manufacturers are aware that time spent on changeover is crucial; however, every second it takes influences efficiency as well as productivity. Decreasing and carefully streamlining changeover time can significantly increase output, thereby reducing costs.

- Top-Notch Precision

Modern laser beam technology is highly precise and produces persistent quality even when used heavily. Most errors occur due to part positioning variations, but laser head technology today uses vision cameras to verify positioning, thereby avoiding errors.

- Faster Processing Speeds

With the ongoing demands in the automotive industry, automobile manufacturers are willing to invest in faster technologies in order to meet their production goals. Laser processing speed makes a compelling difference for automobile manufacturers. In most material processing applications, doubling the laser power implies doubling the processing speed.

- Enhancing Flexibility

Laser cutters are among the most flexible tools due to their versatility and how the technology can be adapted in order to meet the specific requirements of automobile manufacturers.

- Managing Compact Spaces

Manufacturing spaces are undoubtedly costly, so automobile companies want to be as economical as they can when it comes to building out production lines. In such a case, compact machines such as laser cutters are the key to addressing this issue.

End Note

The ability to produce high-end components with speed, high efficiency, as well as flexibility and generate significant cost savings by using lasers have driven the automobile industry towards ever higher adoption of laser technology. The laser market in automobile manufacturing continues to expand at a rapid pace. For the best quality laser solutions, we at Dynotech assure you of the much-needed and top-notch laser solutions to boost your automobile manufacturing efficiency.