Synopsis

Laser cleaving has emerged as a superior solution for optical fibre manufacturing, offering unmatched accuracy and efficiency compared to traditional methods. By using precision laser technology, cleaving provides clean, flat, or angled terminations on fibres, ribbons, connectors, and waveguides. Unlike mechanical termination, laser cleaving ensures minimal damage and superior optical quality, making it indispensable in industries requiring high-performance communication and sensing systems. Dynotech, in collaboration with OpTek Systems, delivers advanced laser cleaving technology that empowers manufacturers with micron-level precision, scalability, and customisation. Its adaptability for coating removal and geometry control enables industries like telecom, healthcare, aerospace, and defence to achieve reliable results. Laser cleaving represents the future of fibre processing, bridging innovation with efficiency in critical manufacturing environments.

Understanding Laser Cleaving Technology

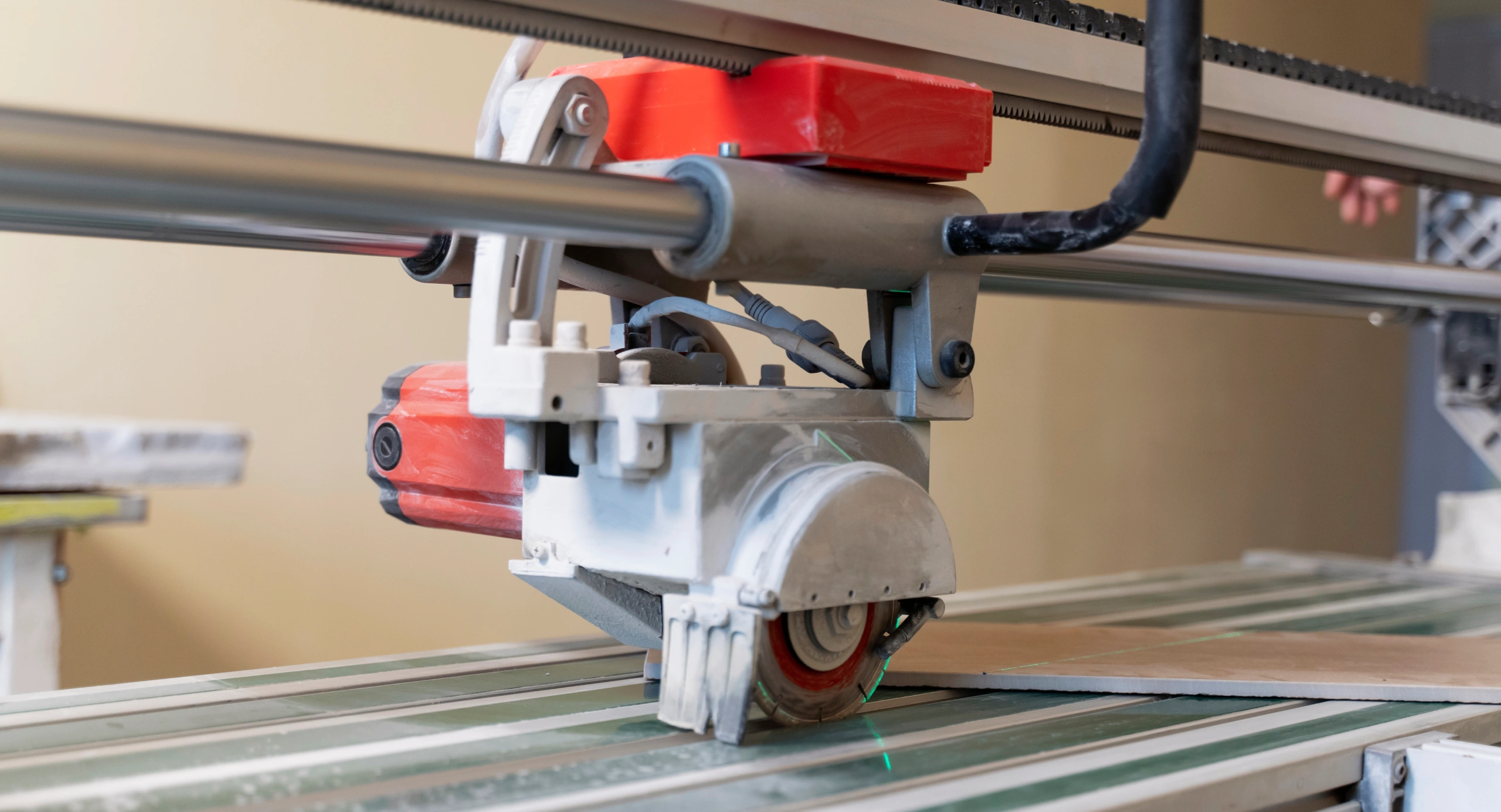

What is Laser Cleaving?

Laser cleaving uses high-precision lasers to terminate optical fibres with flat or angled facets, ensuring superior surface quality and minimal debris.

Advantages of Laser Cleaving Over Mechanical Termination

Superior Optical Quality

Laser cleaving eliminates the inconsistencies of mechanical methods, providing cleaner end faces with reduced losses.

Customisable Geometry

It allows adjustment of end face angles from 0° to over 45°, meeting specific application requirements.

Complete Termination Solution

Laser cleaving can strip polymer coatings, providing a comprehensive solution for fibre termination.

Dynotech’s Advanced Laser Cleaving Solutions

Partnership with Global Leaders

Working with OpTek Systems, Dynotech delivers cutting-edge laser cleaving tailored for complex optical fibre processing.

Micron-Level Precision

Custom solutions enable accurate positioning relative to connectors or packaging features, ensuring performance reliability.

Scalable and Efficient Production

Laser cleaving supports high-speed processing, enabling manufacturers to achieve large-scale production with consistent results.

Industries Leveraging Laser Cleaving

- Telecommunications & Data Centres

-

-

- Aerospace & Defence

- Medical Devices & Healthcare

- Optical Sensing & Instrumentation

- Automotive Electronics

-

FAQs

Laser cleaving is used to terminate optical fibres, ribbons, and connectors with clean, flat, or angled facets, ensuring superior optical quality for communication and sensing applications.

Unlike mechanical termination, which can leave rough edges or debris, laser cleaving delivers precise, clean end faces with minimal damage. This results in reduced optical loss and improved reliability.

Yes, laser cleaving can strip polymer coatings during the process, providing a complete optical fibre termination solution.

Industries like telecommunications, aerospace, healthcare, and automotive rely on laser cleaving for precision and high optical performance.

Laser cleaving offers higher accuracy, scalability, and optical quality compared to mechanical methods, making it the preferred choice for advanced fibre applications.