Synopsis

In the modern automotive landscape, the shift toward electric vehicles (EVs) and smart connectivity has made traditional plastic joining methods obsolete. This blog focuses on the strategic advantages of laser plastic welding for automotive Tier 1 and Tier 2 suppliers. We examine how this technology is becoming the standard for assembling critical components—from sensor housings and ADAS modules to complex fluid tanks and interior displays. By partnering with Evosys Laser Solutions, Dynotech provides the automotive sector with a vibration-free, non-contact process that ensures the integrity of sensitive electronics. We break down the impact of hermetic sealing on vehicle longevity and explain how our modular systems reduce manufacturing footprints. From weight reduction to superior aesthetic finishes, discover how innovative laser technology is helping manufacturers meet the rigorous safety and durability standards of the 21st-century road.

Table of Contents

-

The Automotive Evolution: Plastic as a Structural Material

-

Solving the Electronics Challenge: Vibration-Free Assembly

-

Precision in the EV Ecosystem: Sensors and ADAS

-

Key Benefits for Automotive Reliability

-

100% Hermetic Sealing for Under-the-Hood Components

-

Aesthetics and Invisible Seams for Interior Design

-

Production Readiness: Integrating into High-Speed Lines

-

Why Dynotech? 30 Years of Automotive Process Know-How

The Automotive Evolution: Plastic as a Structural Material

As cars become “computers on wheels,” the number of plastic-housed electronic components has skyrocketed. The Automotive Evolution: Plastic as a Structural Material From radar sensors to infotainment clusters, the demand for joining plastic parts with absolute precision is non-negotiable. Laser plastic welding has emerged as the preferred solution, offering a level of reliability that mechanical fasteners or adhesives simply cannot provide.

Solving the Electronics Challenge: Vibration-Free Assembly

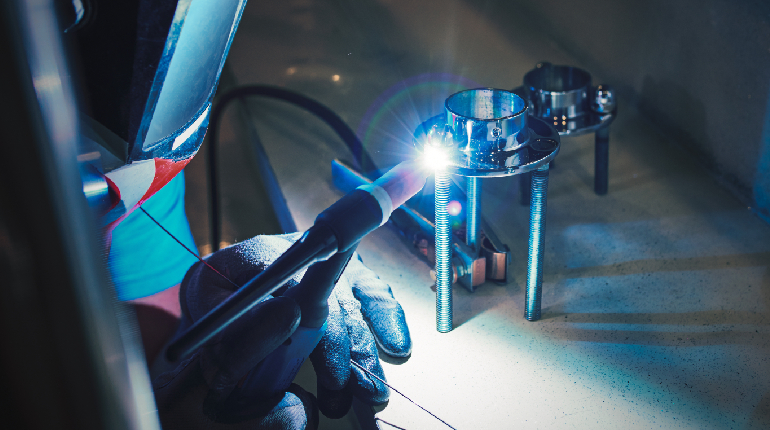

Solving the Electronics Challenge: Vibration-Free Assembly Traditional ultrasonic welding uses high-frequency vibrations that can shatter delicate micro-electronics or loosen pre-soldered components. Laser welding, however, is a non-contact, vibration-free process.

Precision in the EV Ecosystem: Sensors and ADAS

Precision in the EV Ecosystem: Sensors and ADAS This makes it ideal for the Automotive industry’s most sensitive parts, such as Advanced Driver Assistance Systems (ADAS) and Engine Control Units (ECUs), where even a microscopic failure can lead to a safety recall.

Key Benefits for Automotive Reliability

Key Benefits for Automotive Reliability are built into every weld.

100% Hermetic Sealing for Under-the-Hood Components

100% Hermetic Sealing for Under-the-Hood Components Parts located near the engine or on the chassis are exposed to moisture, salt, and oil. Laser welding creates a permanent, molecular bond that is 100% leak-proof, ensuring that fluid tanks and electronic housings remain sealed for the entire life of the vehicle.

Aesthetics and Invisible Seams for Interior Design

Aesthetics and Invisible Seams for Interior Design Modern car interiors demand high-end finishes. Unlike traditional welding, which can leave messy “flash” or visible melt lines, laser welding produces an “invisible” seam. This allows designers to create sleek, high-quality surfaces for dashboards and buttons that look as good as they perform.

Production Readiness: Integrating into High-Speed Lines

Production Readiness: Integrating into High-Speed Lines At Dynotech, we understand that automotive production never stops. Our systems, developed with Evosys Laser Solutions, are designed for high-throughput, 24/7 operation. We provide complete project handling—taking you from material sampling to full production readiness—ensuring that our laser systems integrate seamlessly into your existing robotic cells.

Why Dynotech? 30 Years of Automotive Process Know-How

Why Dynotech? 30 Years of Automotive Process Know-How With decades of experience serving India’s automotive hubs, we bring more than just machines; we bring process authority. Our 100% innovative technology ensures that your production line is future-proofed, helping you deliver safer, lighter, and more reliable vehicles to the global market.

FAQs

Why is laser welding preferred over ultrasonic welding for car sensors?

Laser plastic welding is non-contact and vibration-free. Ultrasonic welding creates high-frequency vibrations that can damage the delicate internal circuits and sensors inside ADAS or ECU modules, whereas laser welding joins the housing without any mechanical stress.

Can laser welding handle the harsh environment of a car engine?

Yes. Laser welding creates a hermetic (leak-proof) seal that is far superior to gaskets or glues. These welds are resistant to the thermal cycling, road salt, and oils commonly found under the hood, ensuring the longevity of the component.

Does the process work on the various types of plastics used in cars?

Automotive manufacturers use a wide range of polymers (e.g., PA, PBT, PC/ABS). As long as one part is laser-transparent and the other is absorbent, laser welding can create a perfect bond. Dynotech provides material sampling to verify your specific polymer combinations.

How fast is the cycle time for an automotive laser welder?

Depending on the size of the part, cycle times can be as low as 2 to 5 seconds. This high-speed performance makes it ideal for the high-volume requirements of the automotive Tier 1 production environment.

Is laser welding more expensive than traditional methods?

While the initial equipment investment may be higher, the cost per part is often lower due to zero consumables (no glue or screws), higher yields (fewer rejects), and the elimination of post-weld cleaning or flashing removal.