Synopsis

As product designs become more intricate and material requirements more demanding, traditional methods like solvent bonding or friction welding are reaching their limitations. This blog explores the sophisticated world of laser plastic welding, a high-end technology that offers a clean, vibration-free, and hermetic joining solution for the modern factory. Through Dynotech’s partnership with Evosys Laser Solutions, we examine the primary plastic welding processes that are redefining standards in the Medical, Automotive, and Consumer Electronics sectors. We break down why laser technology is superior to mechanical methods, focusing on its ability to protect sensitive internal electronics while creating aesthetically perfect seams. From the initial sampling phase to full production readiness, discover how our 30+ years of experience and 100% innovative technology turn your most complex joining challenges into reliable, high-yield manufacturing solutions.

Table of Contents

-

The Shift to High-End Plastic Joining

-

What is Plastic Welding?

-

Comparing Common Processes: Friction, Hot Gas, and Laser

-

The Technical Edge: How Laser Plastic Welding Works

-

Overlap Welding and the Transmission Principle

-

Why the World’s Leading Manufacturers Choose Laser

-

Vibration-Free Joining for Sensitive Electronics

-

Hermetic Sealing for Medical and Healthcare

-

Our Path to Success: From Sampling to Production Readiness

-

Why Dynotech? Global Technology for India’s Major Industries

The Shift to High-End Plastic Joining

In an era where devices are getting smaller and “waterproof” is a standard requirement, how we join plastic components matters more than ever. The Shift to High-End Plastic Joining While many methods exist to fuse polymers, laser plastic welding stands out as the most precise and aesthetically superior choice for high-volume, high-quality production.

What is Plastic Welding?

What is Plastic Welding? At its core, plastic welding is the process of creating a molecular bond between two compatible thermoplastics.

Comparing Common Processes: Friction, Hot Gas, and Laser

Comparing Common Processes: Friction, Hot Gas, and Laser Traditional methods like Friction Welding create heat through mechanical movement, which can generate dust and stress. Hot Gas Welding is effective but often lacks the precision needed for miniature parts. Laser Welding, however, uses a concentrated beam of light to melt the interface without physical contact, offering a level of control that is unmatched by any other technique.

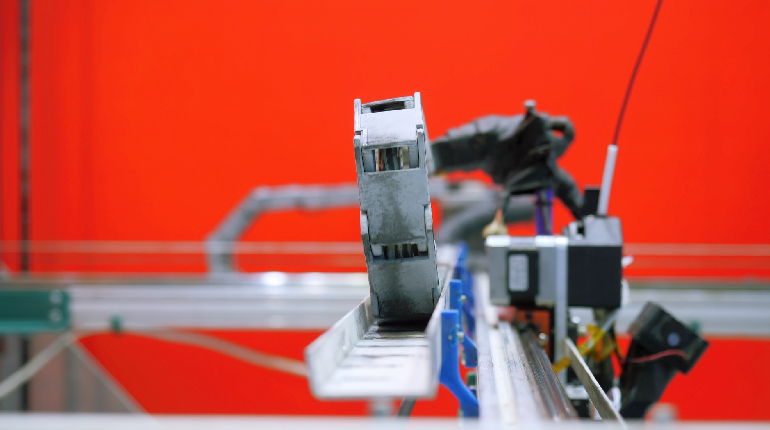

The Technical Edge: How Laser Plastic Welding Works

The Technical Edge: How Laser Plastic Welding Works relies on the “Transmission Principle.”

Overlap Welding and the Transmission Principle

Overlap Welding and the Transmission Principle In this process, the laser beam passes through a transparent upper part and is absorbed by the lower part. The resulting heat melts the interface, and under controlled pressure, a high-strength, hermetic weld is formed. This allows for internal components to be sealed perfectly within a housing without any visible external flash or mess.

Why the World’s Leading Manufacturers Choose Laser

Why the World’s Leading Manufacturers Choose Laser is down to the “cleanliness” of the process.

Vibration-Free Joining for Sensitive Electronics

Vibration-Free Joining for Sensitive Electronics In the Consumer Electronics and Automotive sectors, components like sensors, cameras, and PCBs are extremely sensitive. Mechanical welding methods like ultrasonic welding can vibrate these parts to the point of failure. Laser welding is completely vibration-free, ensuring the integrity of the delicate electronics inside.

Hermetic Sealing for Medical and Healthcare

Hermetic Sealing for Medical and Healthcare is another critical advantage. For diagnostic tools and surgical instruments, the bond must be 100% sterile and leak-proof. Laser welding provides a consistent, high-strength seam that resists chemicals and environmental stress, meeting the rigorous standards of the medical industry.

Our Path to Success: From Sampling to Production Readiness

Our Path to Success: From Sampling to Production Readiness At Dynotech, we don’t just sell machines; we provide a partnership. We accompany you through four critical stages:

- Market Know-How: Applying 30+ years of experience to your specific material challenges.

- Sampling: Testing your parts to find the optimum weld parameters.

- Project Handling: Taking care of the complete integration to save you time.

- Transparency: Ensuring a partnership that guarantees your production success.

Why Dynotech? Global Technology for India’s Major Industries

Why Dynotech? Global Technology for India’s Major Industries Closely working with Evosys Laser Solutions, we bring Italy’s high-end laser technology to India’s most vital sectors, from Aeronautics to Energy. Our mission is to turn your manufacturing challenges into solutions using 100% innovative technology that is built to last.

FAQs

What is the most effective way to weld plastic components?

While several methods exist—including friction, hot gas, and solvent welding—laser plastic welding is considered the most effective for high-precision, high-volume manufacturing. It is non-contact, generates no dust, and creates aesthetically perfect, high-strength bonds.

Can laser welding join two different types of plastic?

Yes, provided the two plastics are “chemically compatible” and have overlapping melting temperature ranges. Dynotech offers sampling services to analyze your material combination and ensure a successful molecular bond.

Why is laser welding preferred for medical devices?

Medical devices require hermetic seals and a highly sterile production process. Laser welding is ideal because it is a “clean” process with no consumables or vibration, ensuring that the internal components remain uncontaminated and the joint is perfectly leak-proof.

Is laser plastic welding suitable for automated production lines?

Absolutely. Our systems, developed with Evosys Laser Solutions, are designed for seamless integration into existing automation platforms. They offer fast cycle times, digital controls, and 100% repeatable results for 24/7 industrial use.

What is the "Transmission Principle" in laser welding?

The Transmission Principle involves one plastic part being “laser-transparent” and the other being “laser-absorbent.” The laser passes through the first part and heats the second at the interface, melting both parts together to create a secure, internal weld.