Synopsis

The vast and rapidly expanding landscape of additive manufacturing can be complex to navigate, whether a business is looking to invest in capital equipment or simply outsource a one-off project. This blog provides a comprehensive guide for anyone seeking the best 3d printing machine or looking to quickly source a reliable 3d printing service. We will dissect the primary financial considerations, offering clarity on the fundamental differences between 3d printing price structures for hardware versus services, and breaking down the key factors that influence overall 3d printing cost. For those prioritizing accessibility and speed, we explore the benefits of using an online 3d printing platform and the advantage of finding a quality 3d printing service near me for faster turnaround and local consultation. Understanding the marketplace, including the reputation and specialization of leading 3d printing companies, is essential for making an informed decision that aligns with production needs. Ultimately, the choice between acquiring a high-value asset and utilizing an on-demand service depends entirely on a careful analysis of the required scale and desired level of internal control.

Table of Contents

-

Buy or Outsource: The Fundamental Decision

-

What to Look for in a 3D Printing Machine

-

FDM – Fused Deposition Modeling

-

Decoding 3D Printing Cost and Price

-

SLS – Selective Laser Sintering

-

The Value of a 3D Printing Service Near Me

-

Online 3D Printing: Speed and Accessibility

-

Choosing the Right Technology Partner

-

Scaling from Service to Ownership

-

Dynotech’s Expertise Across the AM Spectrum

-

Empowering the Next Generation of Indian Design

Buy or Outsource: The Fundamental Decision

The first and most critical decision facing any business considering additive manufacturing is whether to commit to capital expenditure or to outsource production. Purchasing an in-house 3d printing machine provides maximum control over quality, intellectual property, and scheduling, but requires significant upfront investment, maintenance expertise, and space. Conversely, utilizing a 3d printing service offers instant access to a wide array of advanced technologies and materials without any capital risk. The choice is a strategic one, dependent on anticipated usage volume; high-volume production or continuous R&D justifies machine ownership, while sporadic needs are best met by external providers who offer a predictable 3d printing price per part.

What to Look for in a 3D Printing Machine

When planning an in-house deployment, the functionality and capability of the chosen 3d printing machine are paramount. Buyers must consider the required materials (polymers, metals, ceramics), the build volume needed, and the technology type (FDM, SLA, SLS, SLM) based on the application. For instance, high-resolution aesthetic prototypes require stereolithography (SLA), while strong, functional end-use parts demand Selective Laser Sintering (SLS) or metal fusion. A thorough evaluation of the machine’s speed, reliability, and the availability of technical support is necessary to ensure the asset can sustain continuous operation and justify its significant 3d printing price.

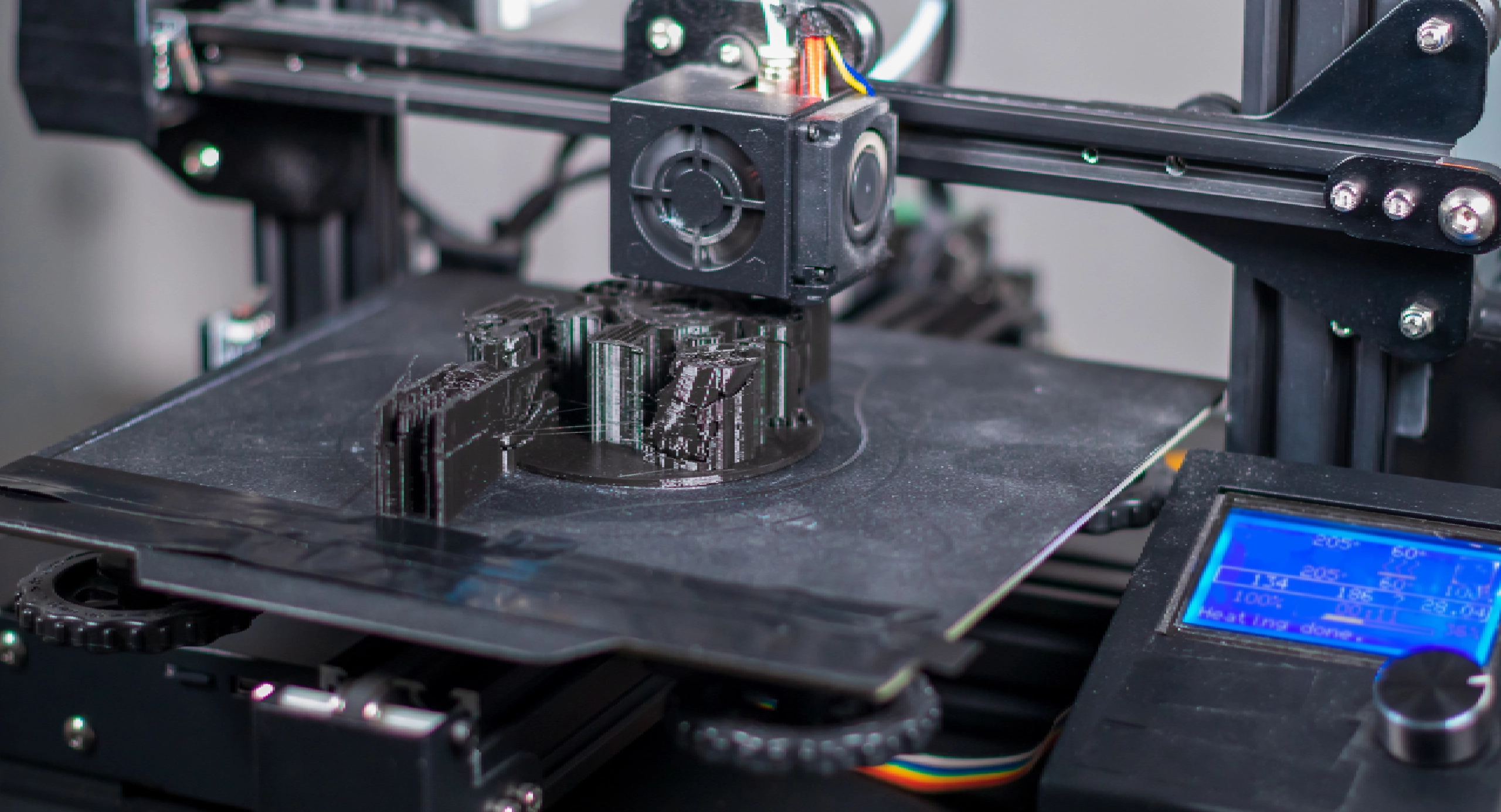

FDM – Fused Deposition Modeling

FDM (Fused Deposition Modeling) technology represents the most accessible entry point for a 3d printing machine, known for its reliability and low operational 3d printing cost. This technique builds parts layer by layer from extruded thermoplastic filament. FDM is excellent for low-stress functional prototypes, concept modeling, and creating quick-turn manufacturing tools and jigs. Its wide material compatibility and simple operation make it a staple in any R&D lab or engineering classroom, offering a highly economical solution for basic online 3d printing needs.

Decoding 3D Printing Cost and Price

Understanding the financial structure of additive manufacturing is essential for budgetary success. Breaking down the 3d printing cost involves separating materials, labor, post-processing, and machine amortization. For an outsourced service, the 3d printing price per part is heavily influenced by the volume of material used and the time the machine takes to print the part. Buyers should obtain itemized quotes to ensure they are comparing apples to apples—a simple FDM part will have a vastly different 3d printing price than a highly complex, metal part requiring extensive post-processing. Strategic use of materials and careful 3d printing design optimization can dramatically reduce the final per-part cost.

SLS – Selective Laser Sintering

SLS (Selective Laser Sintering) is a premium 3d printing machine technology that fuses powdered thermoplastics, such as nylon, with a laser. This process offers superior mechanical strength, excellent chemical resistance, and the ability to create complex, functional parts without any support structures. While commanding a higher 3d printing price and material cost than FDM, SLS is essential for producing end-use components, high-stress functional prototypes, and highly intricate assemblies, making it the technology of choice for demanding 3d printing companies in the aerospace and medical sectors.

The Value of a 3D Printing Service Near Me

For time-sensitive projects or complex materials, searching for a quality 3d printing service near me offers distinct advantages over remote suppliers. A local provider allows for direct consultation with application engineers, instant clarification of file geometry, and the ability to hand-deliver and inspect prototypes, leading to a much faster, more efficient iteration cycle. The reduction in shipping time and cost can significantly influence the overall 3d printing cost and accelerate time-to-market. Furthermore, a relationship with a local provider allows for greater flexibility in managing urgent, last-minute production needs.

Online 3D Printing: Speed and Accessibility

The convenience of online 3d printing platforms has democratized access to advanced manufacturing technologies globally. These services allow users to upload CAD files, select materials and finishing options, and receive an instant 3d printing quote for rapid production. This model is exceptionally effective for conceptual prototyping, low-volume custom parts, and for users who need access to specialized 3d printing machine types that would be prohibitively expensive to own in-house. While convenient, users should ensure the 3d printing companies running the platform utilize industrial-grade equipment, not consumer-level printers, to guarantee part accuracy and quality.

Choosing the Right Technology Partner

Identifying the best technology partner requires evaluating the specialization and reputation of the 3d printing companies in the market. The ideal partner should possess a diverse portfolio of technologies (FDM, SLA, SLS, Metal AM) and demonstrate deep application expertise. Their ability to guide a client on material selection and provide process optimization advice is far more valuable than simply offering the lowest 3d printing price. A reliable partner will help a business navigate the complexities of certifications and provide the necessary after-sales support, whether they are selling a 3d printing machine or providing a 3d printing service.

Scaling from Service to Ownership

For businesses experiencing rapid growth, a strategic path from outsourcing to ownership must be planned. Initially utilizing an online 3d printing service is wise, but once usage volume crosses a certain threshold, the accumulating 3d printing cost will eventually justify the upfront investment in a dedicated 3d printing machine. This threshold can be identified by meticulously tracking all outsourced 3d printing service near me expenditures. When the total annual cost of services approaches the capital cost of a suitable machine, the move to ownership becomes a clear economic imperative, allowing the business to capture the long-term value and control.

Dynotech’s Expertise Across the AM Spectrum

Dynotech Instruments Pvt. Ltd. acts as a strategic partner, bridging the gap between global additive technology leaders and Indian industry. We provide access to the best-in-class industrial 3d printing machine systems, encompassing metal AM, SLS, and FDM technologies, ensuring our clients receive the most robust and reliable hardware available.

Empowering the Next Generation of Indian Design

Whether a client requires a quick 3d printing quote for a specialized 3d printing service project or a comprehensive strategy for industrial 3d printing ownership, Dynotech offers the expertise to navigate the complex factors of 3d printing price and technology selection. We are committed to empowering local 3d printing companies and manufacturers with the tools and knowledge necessary for competitive advantage in the global market.

FAQs

What key factors determine the final 3d printing price when ordering from a 3d printing service?

The final 3d printing price charged by a 3d printing service is determined by several core factors: the volume of material consumed (which dictates weight and raw material cost), the type of technology used (SLS or Metal AM are more expensive than FDM), the labor required for post-processing (support removal, polishing, coating), and the time the 3d printing machine is occupied (build time). Complex geometries, large parts, and exotic materials significantly increase the overall 3d printing cost, making it crucial to get a detailed 3d printing quote that itemizes these factors.

How can a business find the best 3d printing service near me for rapid prototyping needs?

To find the best 3d printing service near me, a business should utilize online directories, local manufacturing forums, and networking events, focusing on providers with industrial-grade equipment. The advantage of local service is faster turnaround times, often reducing the overall 3d printing cost due to lower shipping fees and the ability to directly consult with engineers for design optimization. Before committing, compare the range of materials and technologies offered, ensuring the local 3d printing service near me can handle both basic FDM and advanced SLS or SLA requirements for functional prototypes.

What is the difference between 3d printing price and 3d printing cost, and how are they relevant to ownership?

3d printing price typically refers to the one-time, upfront charge of purchasing a 3d printing machine or the fee paid to a service provider for a single part. 3d printing cost, in contrast, refers to the Total Cost of Ownership (TCO) over the machine’s lifespan. This includes material, utilities, labor, maintenance, and amortization. Understanding the 3d printing cost is critical, as a lower-priced machine may have a higher long-term cost due to expensive proprietary materials or frequent maintenance, influencing the ultimate profitability of internal online 3d printing operations.

What should a company prioritize when choosing between different 3d printing companies for a large-scale project?

When choosing between different 3d printing companies for a large-scale project, a company should prioritize reliability, capacity, and expertise. Reliability is assessed through the quality of the 3d printing machine fleet and their maintenance records. Capacity means the provider must be able to scale production across multiple industrial machines without compromising quality. Expertise ensures the 3d printing service can advise on the optimal material and technology choice for high-volume functional requirements, mitigating risks and ensuring the final part quality aligns with the original 3d printing design.

When does the accumulating 3d printing cost justify the investment in a dedicated 3d printing machine?

The accumulating 3d printing cost justifies the investment in a dedicated 3d printing machine when the total annual expenditure on outsourced online 3d printing services approaches the capital purchase price of a suitable industrial-grade machine. At this point, the business gains full control over intellectual property, production scheduling, and material choice, while ensuring that the investment cost is rapidly recouped. Moving to ownership transforms the variable expense of the 3d printing service into a manageable fixed asset, providing a sustainable, long-term economic advantage.