Synopsis

In the fast-paced world of electronics manufacturing, the drive toward miniaturization and high-density component placement has rendered traditional mechanical depaneling methods obsolete. This blog explores the transformative benefits of Laser PCB Routing and Depaneling, a stress-free separation process delivered through Dynotech’s partnership with DCT Laser Solutions GmbH. We examine how high-precision lasers eliminate the risks of mechanical vibration, milling dust, and micro-cracking, which are common with traditional routers. By detailing features like optical fiducial recognition and the ability to process flexible, flex-rigid, and thin rigid PCBs, we demonstrate how manufacturers can maximize panel density and reduce material waste. Whether you are aiming for “zero-stress” processing of sensitive modules or looking to integrate a high-throughput inline solution, discover why laser technology is the future of high-yield electronic assembly.

Table of Contents

-

The Evolution of PCB Separation: Beyond the Milling Bit

-

DCT Laser Solutions: A Partnership in Precision

-

Smart, Digitally Controlled Accuracy

-

Overcoming the Limitations of Traditional Depaneling

-

Eliminating Mechanical Stress and Micro-Cracking

-

Maximizing Board Density and Material Usage

-

Flexibility Across Substrates: Rigid, Flex, and Flex-Rigid

-

Why Dynotech? Reliability, Uptime, and Future-Ready Integration

The Evolution of PCB Separation: Beyond the Milling Bit

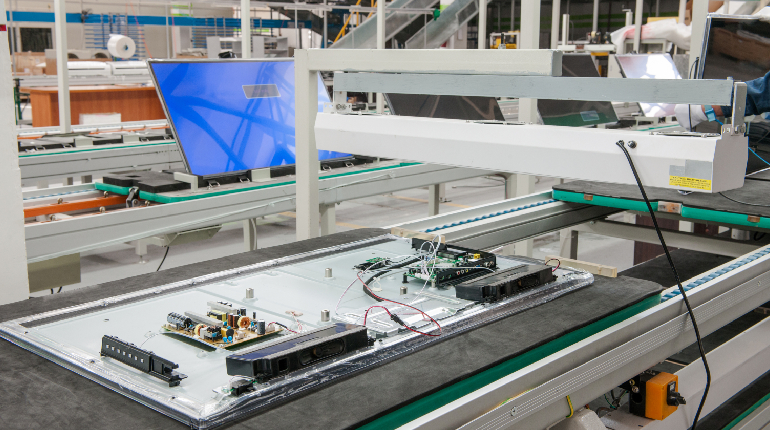

As printed circuit boards become thinner and more densely populated, the final step of “separating” them from the panel has become a high-risk operation. The Evolution of PCB Separation: Beyond the Milling Bit Mechanical routing and “V-scoring” exert significant physical stress on the board, often leading to fractured solder joints or damaged capacitors. Laser PCB Routing and Depaneling solves this by using a high-precision laser beam to separation modules with zero mechanical contact.

DCT Laser Solutions: A Partnership in Precision

Through our collaboration with DCT Laser Solutions GmbH, Dynotech brings Europe’s leading laser technology to the Indian electronics sector. DCT Laser Solutions: A Partnership in Precision Our systems are designed for the most demanding production environments.

Smart, Digitally Controlled Accuracy

Smart, Digitally Controlled Accuracy By utilizing advanced digital controls and optical recognition of fiducials, our machines automatically compensate for panel deformation. This ensures that every cut is consistently accurate, regardless of minor variations in the material.

Overcoming the Limitations of Traditional Depaneling

Overcoming the Limitations of Traditional Depaneling is essential for modern quality standards.

Eliminating Mechanical Stress and Micro-Cracking

Eliminating Mechanical Stress and Micro-Cracking Because the laser is a non-contact tool, it transfers zero vibration to the board. This “stress-free” processing is critical for protecting delicate components like MEMS sensors or tiny 0201 packages. Milling Dust vs. Laser Cleanliness Mechanical routers produce significant milling dust that can contaminate sensitive optics or electrical contacts. Laser depaneling delivers exceptionally clean cuts, eliminating the need for post-process cleaning and increasing overall reliability.

Maximizing Board Density and Material Usage

Maximizing Board Density and Material Usage is a direct path to cost-efficiency. Traditional routers require wide “buffer paths” for the milling bit to travel. Because the laser beam is microscopic, these paths can be significantly narrower. This allows for more modules per panel, directly reducing material waste and lowering the overall cost per PCB.

Flexibility Across Substrates: Rigid, Flex, and Flex-Rigid

Flexibility Across Substrates: Rigid, Flex, and Flex-Rigid Modern designs often utilize unconventional materials. Our laser technology excels at cutting flexible circuits and flex-rigid hybrids where traditional mechanical tools would cause delamination or tearing. For thin rigid PCBs, the absence of mechanical cutting dyes means you can implement intricate designs and rapid design changes without the expense of new tooling.

Why Dynotech? Reliability, Uptime, and Future-Ready Integration

Why Dynotech? Reliability, Uptime, and Future-Ready Integration With 30+ years of experience, we understand that your production line cannot afford downtime. Our systems feature minimal moving parts, resulting in reduced wear and maximum uptime compared to mechanical routers. Whether you need a standalone manual workstation or a fully automated inline solution for high-throughput manufacturing, Dynotech provides the expert guidance and technical support needed to transform your PCB assembly process.

FAQs

What is the main advantage of laser PCB depaneling?

The primary advantage is stress-free processing. Unlike mechanical routers, the laser is non-contact and produces no vibrations. This protects sensitive electronic components and solder joints from micro-cracking and mechanical failure, which is vital for high-density and delicate boards.

Can laser depaneling handle flexible and rigid PCBs?

Yes. Laser routing technology is incredibly versatile and can process flexible, flex-rigid, and thin rigid PCBs. It is especially useful for flexible circuits where mechanical tools often cause tearing or delamination.

How does laser routing save on material costs?

Because the laser beam is much thinner than a mechanical milling bit, the “kerf” (cut width) is significantly smaller. This allows components to be placed closer together on the panel, enabling a higher number of modules per board and reducing material waste.

Is there a lot of maintenance involved in these systems?

No. Compared to mechanical routers, laser systems have minimal moving parts and no physical bits that wear out or break. This translates to lower maintenance requirements, fewer production interruptions, and significantly higher uptime.

Can I integrate a laser depaneling machine into my existing inline production?

Absolutely. We offer various designs, including inline solutions for seamless material transfer. These are designed for high-throughput environments and can interface directly with your existing conveyor systems and automation platforms.