Synopsis

The fabrication industry is in the midst of a pivotal transformation, shifting from traditional plasma and stamping methods to embrace the micron-level accuracy of laser technology. At the forefront of this revolution is the 3d laser metal cutting machine, which offers geometric flexibility far beyond conventional two-axis systems. This blog provides a detailed overview of this cutting-edge equipment, examining why the modern 3d metal cutter has become indispensable across sectors like aerospace, automotive, and heavy machinery. We will delve into the critical factors that drive the market, particularly the role of specialized metal laser cutting machine manufacturers in india who are bringing global technology to the local ecosystem. Understanding the investment landscape is crucial; therefore, we will address key financial considerations, including the 3d metal laser cutting machine price and the related 3d laser cutting machine price in india for specific configurations. Furthermore, we explore the benefits of advanced software and motion control, which allow for true five-axis work and intricate bevel cutting, elevating the capabilities of 3d laser cutting metal applications. Finally, we analyze the competitive pricing environment, looking at the full spectrum of costs, including the cnc metal laser cutting machine price in india, ensuring manufacturers are equipped to make a sound, profitable investment in the future of precision fabrication.

Table of Contents

-

The Dawn of Multi-Axis Fabrication

-

Unlocking Design Freedom with 3D Laser Cutting Metal

-

The Engine of Accuracy: What Defines a 3D Metal Cutter

-

Wide Power Range (3KW to 60KW)

-

Investment Insight: Understanding the Machine Price Landscape

-

The Role of Metal Laser Cutting Machine Manufacturers in India

-

Advanced Welding and Cleaning Systems

-

Comparing 3D Laser with Traditional CNC Methods

-

Future-Proofing Production with Advanced Technology

-

Dynotech’s Vision for Precision Engineering

-

Empowering India’s Industrial Growth

The Dawn of Multi-Axis Fabrication

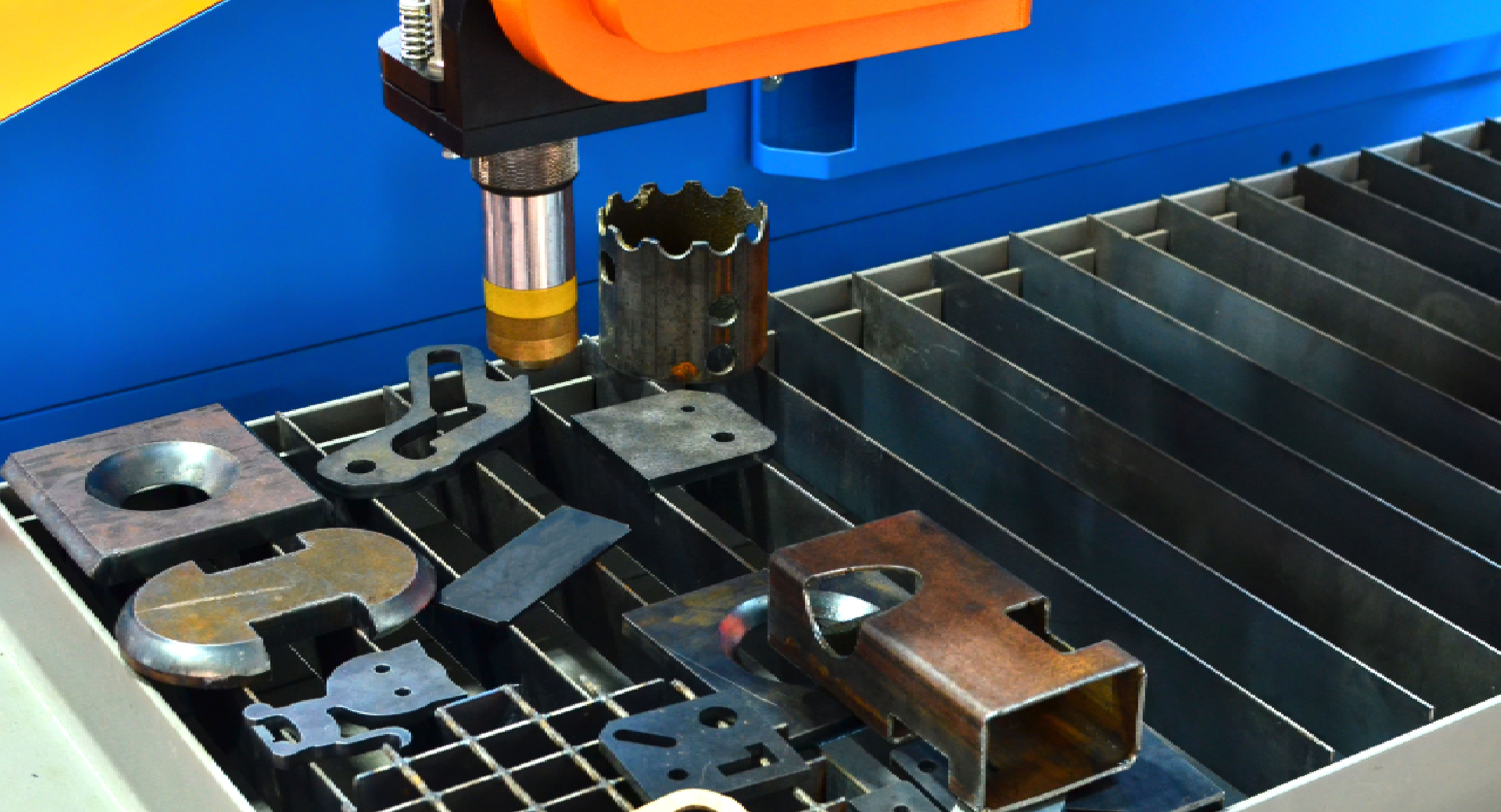

Modern engineering demands componentry that is complex, lightweight, and manufactured with virtually zero tolerance for error, pushing the boundaries of traditional two-dimensional fabrication. This intensive requirement for precision on three-dimensional parts has made the 3d laser metal cutting machine an essential tool in any advanced manufacturing facility. Unlike standard 2D laser tables that only cut flat sheet material, these sophisticated systems incorporate multiple axes of motion, often five or six, enabling the cutting head to manipulate the laser beam around pre-formed, stamped, or tubular components. This capability significantly reduces the need for secondary processes, such as machining or trimming, which inherently introduce error and increase cycle time. The resulting efficiency gain and superior edge quality solidify the laser cutter’s position as the paramount technology for serious industrial players.

Unlocking Design Freedom with 3D Laser Cutting Metal

The true value of a 3d laser metal cutting machine lies in its capacity to unlock design freedom previously constrained by manufacturing limitations. Components can now be designed for optimal performance—maximizing strength while minimizing weight—without concern for the limitations of tooling or dies. The process of 3d laser cutting metal allows for highly intricate hole patterns, complex curved trims, and precise bevel edges to be cut into pre-bent materials, often eliminating the need for complex, costly, and slow punching or trimming dies. This acceleration of the process, combined with the extreme edge cleanliness and minimal heat-affected zone, ensures that the structural integrity of the metal is maintained, a critical requirement for safety components in automotive and aerospace industries.

The Engine of Accuracy: What Defines a 3D Metal Cutter

At its core, the 3d metal cutter is defined by its ability to maintain micron-level accuracy across complex spatial coordinates. (The Engine of Accuracy: What Defines a 3D Metal Cutter – H3) This precision is achieved through a combination of high-speed fiber laser sources and sophisticated, continuous-path CNC control systems that can manage up to five axes simultaneously. The dynamic focusing optics and rapid response of the cutting head allow the machine to maintain a consistent standoff distance and beam focus regardless of the part’s contour variations. Furthermore, many systems integrate advanced sensors and vision systems that automatically detect the part’s exact position and compensate for minor stamping or forming errors, ensuring the cutting path is perfectly executed every single time, which is key to repeatable quality in mass production.

Wide Power Range (3KW to 60KW)

Our advanced laser metal cutting solutions, in collaboration with global partners like Penta Laser, offer a colossal power range from 3KW for fine precision work to an industry-leading 60KW for processing the thickest metal plates and highest-speed applications. This versatility ensures that whether a manufacturer is dealing with thin stainless steel sheets requiring ultra-clean cuts or thick carbon steel for heavy machinery, there is a laser configuration available to meet the specific processing need. This ability to scale power output without sacrificing beam quality or motion control is a key differentiator in the competitive global fabrication market.

Investment Insight: Understanding the Machine Price Landscape

For manufacturers, the discussion around technology quickly leads to investment and pricing, making the cost of entry a primary consideration. Factors influencing the 3d metal laser cutting machine price are numerous, encompassing the kilowatt rating, the number of axes, the size of the working envelope, and the inclusion of automation features like pallet changers. While the initial 3d laser cutting machine price in india might seem high compared to traditional equipment, the return on investment is realized quickly through scrap reduction, the elimination of secondary processes, and massive cycle time improvements. Buyers must also consider the cost of related equipment, such as the comprehensive cnc metal laser cutting machine price in india, which integrates the cutting system with the motion control unit and software for seamless operation.

The Role of Metal Laser Cutting Machine Manufacturers in India

The local ecosystem of metal laser cutting machine manufacturers in india plays a vital role in technology adoption, making global standards accessible and locally supported. These companies act as critical links, offering localized training, installation, and essential after-sales support that is necessary for maximizing machine uptime and ensuring long-term profitability. Furthermore, local manufacturers often collaborate with international technology providers to tailor machine configurations and software specifically to the unique material requirements and operational challenges faced by Indian industries. Choosing a reputable manufacturer with strong local presence guarantees access to prompt maintenance and readily available spare parts, minimizing costly production interruptions.

Advanced Welding and Cleaning Systems

Beyond cutting, Dynotech offers integrated systems for metal welding and surface cleaning, designed to complement our high-power cutting machines. The welding systems, engineered in partnership with technology leaders, deliver precise, reliable metal joining with minimal distortion, crucial for high-strength applications. Simultaneously, our cleaning systems utilize laser technology to remove rust, paint, and contaminants from metal surfaces before welding or finishing, enhancing joint integrity and aesthetic quality. This capability provides a comprehensive solution for metal fabrication shops, allowing for end-to-end processing—cutting, cleaning, and welding—within the same automated workspace.

Comparing 3D Laser with Traditional CNC Methods

When juxtaposing modern 3D laser cutting with conventional CNC plasma or routing methods, the differences in precision and material efficiency are stark. Plasma cutting is fast but leaves a wide kerf, rough edges, and a large heat-affected zone, often necessitating time-consuming grinding or finishing steps. Conversely, the 3d metal cutter produces a clean, polished edge in a single pass, eliminating post-processing entirely and drastically reducing part lead time. While the initial cnc metal laser cutting machine price in india might be higher than traditional alternatives, the efficiency of the laser method ensures far greater material utilization, lower labor costs, and superior geometric accuracy, making it the clear choice for advanced manufacturing.

Future-Proofing Production with Advanced Technology

Investing in a high-quality 3d laser metal cutting machine is essentially an investment in future-proofing manufacturing capabilities. As product life cycles shorten and consumer demands for customization and quality increase, the ability to quickly pivot and produce complex parts without reliance on expensive physical tooling becomes indispensable. The continuous evolution of fiber laser technology, combined with ever-improving motion controls, ensures that the current generation of these machines will remain relevant and highly productive for many years to come, offering a sustainable competitive advantage in a rapidly evolving global economy.

Dynotech’s Vision for Precision Engineering

Dynotech Instruments Pvt. Ltd. is proud to be at the forefront of this industrial revolution, partnering exclusively with global leaders like Penta Laser to bring state-of-the-art metal cutting and welding solutions to India. We are committed to supplying not only the best-in-class 3d laser metal cutting machine systems but also the full spectrum of support, from advisory services to precision installation, ensuring optimal performance from day one.

Empowering India's Industrial Growth

Our vision is to empower Indian industries, providing high-quality, high-performance instruments and reliable technical expertise necessary to excel in precision engineering. By delivering advanced solutions across the full 3d metal laser cutting machine price and power range, Dynotech ensures local manufacturers can achieve world-class quality, operational efficiency, and sustainable cost-saving advantages.

FAQs

What capabilities distinguish a modern 3d laser metal cutting machine from traditional 2D flatbed cutters?

The defining capability of a modern 3d laser metal cutting machine is its multi-axis functionality, typically five or more, which allows the laser head to move freely and manipulate the cutting beam around a pre-formed or three-dimensional object. Unlike 2D cutters, which are limited to flat sheet metal, the 3D system can perform intricate cuts, bevels, and trims on curved surfaces, tubes, and stamped components. This ability to cut in three dimensions eliminates the need for manual trimming or expensive dedicated stamping dies, thereby simplifying the production workflow and enabling the creation of complex parts with superior accuracy, which is essential for high-tolerance industries.

What key factors determine the final 3d metal laser cutting machine price for a potential buyer?

The final 3d metal laser cutting machine price is influenced by several critical specifications, starting with the laser power (measured in kilowatts), which affects cutting speed and material thickness capacity. The number of axes (5-axis, 6-axis) and the overall working envelope size also play a major role. Furthermore, the inclusion of sophisticated automation features, such as robotic loading, part unloading systems, and high-end continuous-path cnc metal laser cutting machine price in india controls, significantly impacts the total investment. Buyers must also factor in the reputation and local support network of the metal laser cutting machine manufacturers in india to ensure reliable service and long-term machine uptime.

How does the process of 3d laser cutting metal improve efficiency in manufacturing complex components?

The process of 3d laser cutting metal dramatically improves efficiency by consolidating multiple manufacturing steps into a single operation. It replaces traditional methods like punching, routing, and manual finishing by delivering precise cuts on complex contours in one pass. Since the 3d metal cutter is digitally controlled, changeovers between different part geometries are instantaneous, requiring only a new program upload rather than expensive, time-consuming physical tooling changes. This agility not only reduces labor and setup time but also virtually eliminates material distortion and secondary processing requirements, leading to faster lead times and higher component quality.

Why is the local presence of metal laser cutting machine manufacturers in India important for industrial clients?

The local presence of metal laser cutting machine manufacturers in india is crucial for ensuring timely service and maximizing machine uptime. While the technology originates globally, successful operation relies on reliable domestic support for installation, operator training, process optimization, and, most importantly, rapid access to spare parts. A strong local network guarantees that technical issues can be resolved quickly, minimizing costly production interruptions. Furthermore, local manufacturers often tailor their machine software and configurations to best suit the specific environmental conditions and material standards prevalent in the Indian market, ensuring optimal performance and application fit.

What is the typical investment range for a high-quality 3d laser cutting machine price in india and what benefits offset this cost?

The 3d laser cutting machine price in india for a high-quality, multi-axis system represents a substantial capital investment, varying widely based on power and configuration. While the specific price depends on market dynamics, the cost is offset by significant long-term benefits. These include a major reduction in per-part production cost due to faster cycle times and the elimination of secondary finishing processes. Furthermore, the increased precision and material efficiency, coupled with the ability to produce complex, high-value parts, lead to a rapid return on investment. The technology’s reliability and superior quality make it essential for companies looking to maintain a competitive edge and secure high-value contracts.