Synopsis

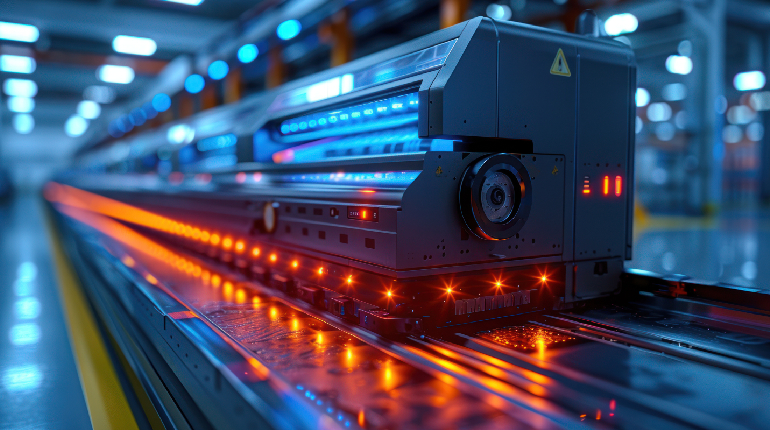

In high-end manufacturing, the laser source is only half of the equation; the ability to guide, shape, and focus that light determines the final quality of the part. This blog explores precision laser beam micromachining, focusing on the critical role of laser beam delivery systems. We examine how Dynotech’s partnership with Haas LTI provides the modular hardware necessary to handle any wavelength and power level. We break down the technical components of the 12mm, 19mm, 25mm, 38mm, and 50mm series, detailing how mirrors, collimators, and focus heads work in harmony to achieve micron-level accuracy. From drilling and marking to cladding and laser hardening, discover how a robust beam delivery system ensures consistent results across all materials. Whether you are building a custom fiber-delivered system or integrating beam enhancement tools, this guide explains why the right delivery hardware is the heartbeat of industrial laser success.

Table of Contents

-

The Bridge Between Light and Material

-

Haas LTI: Global Standards in Beam Delivery

-

Modularity: Custom Configurations for Every Wavelength

-

Navigating the Series: 19mm to 50mm Hardware

-

Beam Directing, Positioning, and Viewing

-

Beam Enhancement and Position Viewing

-

Specialized Focus: Fiber & Fiber Delivered Lasers

-

Industrial Applications: Beyond Simple Cutting

-

Why Dynotech? Reliability Through Technical Knowledge

The Bridge Between Light and Material

A laser source produces raw energy, but without a sophisticated delivery path, that energy is untamed. The Bridge Between Light and Material Laser beam delivery refers to the complex assembly of hardware—shutters, mirrors, collimators, and focus heads—that transports the beam to the workpiece. In precision laser beam micromachining, even a fraction of a millimeter of misalignment can ruin a high-value component, making the precision of the delivery system paramount.

Haas LTI: Global Standards in Beam Delivery

Through our collaboration with Haas LTI, Dynotech brings world-class expertise to the Indian market. Haas LTI: Global Standards in Beam Delivery With decades of experience, Haas LTI provides the robust components required to survive the rigors of 24/7 industrial use. Modularity:

Modularity: Custom Configurations for Every Wavelength

Custom Configurations for Every Wavelength Our products are inherently modular. This allows us to design custom configurations for UV, Green, Fiber, or CO2 lasers using standard components, ensuring that your specific wavelength is delivered with maximum efficiency and minimum beam divergence.

Navigating the Series: 19mm to 50mm Hardware

Navigating the Series: 19mm to 50mm Hardware allows manufacturers to scale their systems based on beam diameter and power.

- 19mm & 25mm Series: Ideal for low-to-medium power applications like marking and micro-drilling.

- 38mm & 50mm Series: Built for high-power industrial processing, including heavy-duty welding and cladding.

Beam Directing, Positioning, and Viewing

Beam Directing, Positioning, and Viewing hardware ensures the beam stays on target. Using high-grade mirrors and precision mounts, we can redirect light around obstacles or into tight spaces.

Beam Enhancement and Position Viewing

Beam Enhancement and Position Viewing tools, such as beam expanders and specialized adapters, allow operators to visualize the beam’s position relative to the workpiece, ensuring “first-time-right” accuracy.

Specialized Focus: Fiber & Fiber Delivered Lasers

As fiber lasers become the industry standard, our Fiber & Fiber Delivered Lasers series provides specialized solutions. Specialized Focus: Fiber & Fiber Delivered Lasers Ranging from the compact 12mm series to high-power 10kW systems, these components are engineered to handle the intense energy density of fiber light. We also provide critical accessories like 3029 and 3049 series nozzle bodies, which ensure optimal gas flow during the cutting or welding process.

Industrial Applications: Beyond Simple Cutting

Industrial Applications: Beyond Simple Cutting span the entire manufacturing spectrum. Precision beam delivery is the core of:

- Micro-Drilling: Creating cooling holes in turbine blades.

- Laser Hardening: Improving wear resistance in automotive gears.

- Cladding: Adding high-performance alloys to base metals.

- Precision Marking: Applying permanent identifiers to medical implants.

Why Dynotech? Reliability Through Technical Knowledge

Why Dynotech? Reliability Through Technical Knowledge With 30+ years of experience, we understand that every micron counts. We don’t just supply parts; we provide a complete, robust, and reliable solution tailored to your material processing needs. Our mission is to ensure that your laser beam delivery system is an asset that enhances your production quality and maximizes your ROI.

FAQs

What exactly is a laser beam delivery system?

A laser beam delivery system is the collective hardware used to transport the laser beam from the source (the resonator) to the workpiece. This includes mirrors to redirect light, collimators to straighten the beam, and focus heads to concentrate the energy at the point of processing.

Why is modularity important in laser delivery?

Modularity allows for custom configurations. Since different materials and processes require different wavelengths and power levels, modular components (like those from Haas LTI) can be swapped or rearranged to suit a specific application without needing a completely new machine.

What is the difference between the 19mm and 50mm series?

The measurement (e.g., 19mm or 50mm) refers to the clear aperture or the diameter of the optics. The 19mm series is typically used for smaller, lower-power beams, while the 50mm series is designed for larger, high-power beams (up to several kilowatts) used in heavy industrial welding and cutting.

Can these systems handle fiber lasers up to 10kW?

Yes. Our specialized Fiber & Fiber Delivered Lasers series includes components rated for power levels from 500W up to 10kW. These are engineered with high-threshold optics and cooling systems to handle the extreme energy of modern industrial fiber lasers.

What role do nozzle bodies play in laser processing?

Nozzle bodies (such as the 3014 or 3029 series) are the final point of delivery. They direct the assist gas (like Oxygen or Nitrogen) alongside the laser beam. Proper nozzle design is critical for achieving clean cuts, preventing spatter during welding, and protecting the optics from debris.