Synopsis

The pursuit of precision, speed, and integrity in metal joining has made laser technology the cornerstone of modern industrial fabrication. The contemporary metal laser welding machine represents a monumental leap forward from traditional arc-based processes, offering unparalleled control over the weld pool and heat input. This blog serves as a definitive guide to the robust laser welding equipment driving high-volume manufacturing across various sectors, from aerospace to heavy machinery. We delve into the technical differentiators, exploring the capabilities of the industrial fiber laser welding machine, known for its superior beam quality and efficiency. We also discuss the flexibility offered by a modern laser welding machine portable unit, which brings precision to the shop floor. Understanding the full scope of applications, including systems that combine functions like a specialized laser cutting welding machine, is crucial for manufacturers seeking maximum asset utility. Ultimately, the integration of advanced laser machine welding systems, from the core welding machine laser source to the delivery optics, is essential for maintaining a competitive edge and meeting stringent quality standards globally.

Table of Contents

-

The New Standard in Metal Joining

-

The Fiber Laser Welding Machine: Power and Efficiency

-

Laser Beam Delivery Systems

-

Applications of Laser Machine Welding

-

Metal Cutting and Welding Systems (Penta Laser)

-

Laser Welding Machine Portable: Agility in Fabrication

-

Maximizing Utility: The Laser Cutting Welding Machine

-

Investment and Operational Advantages

-

Ensuring Weld Integrity and Quality Control

-

Dynotech’s Expertise in Advanced Fabrication

-

Partnering for Manufacturing Excellence in India

The New Standard in Metal Joining

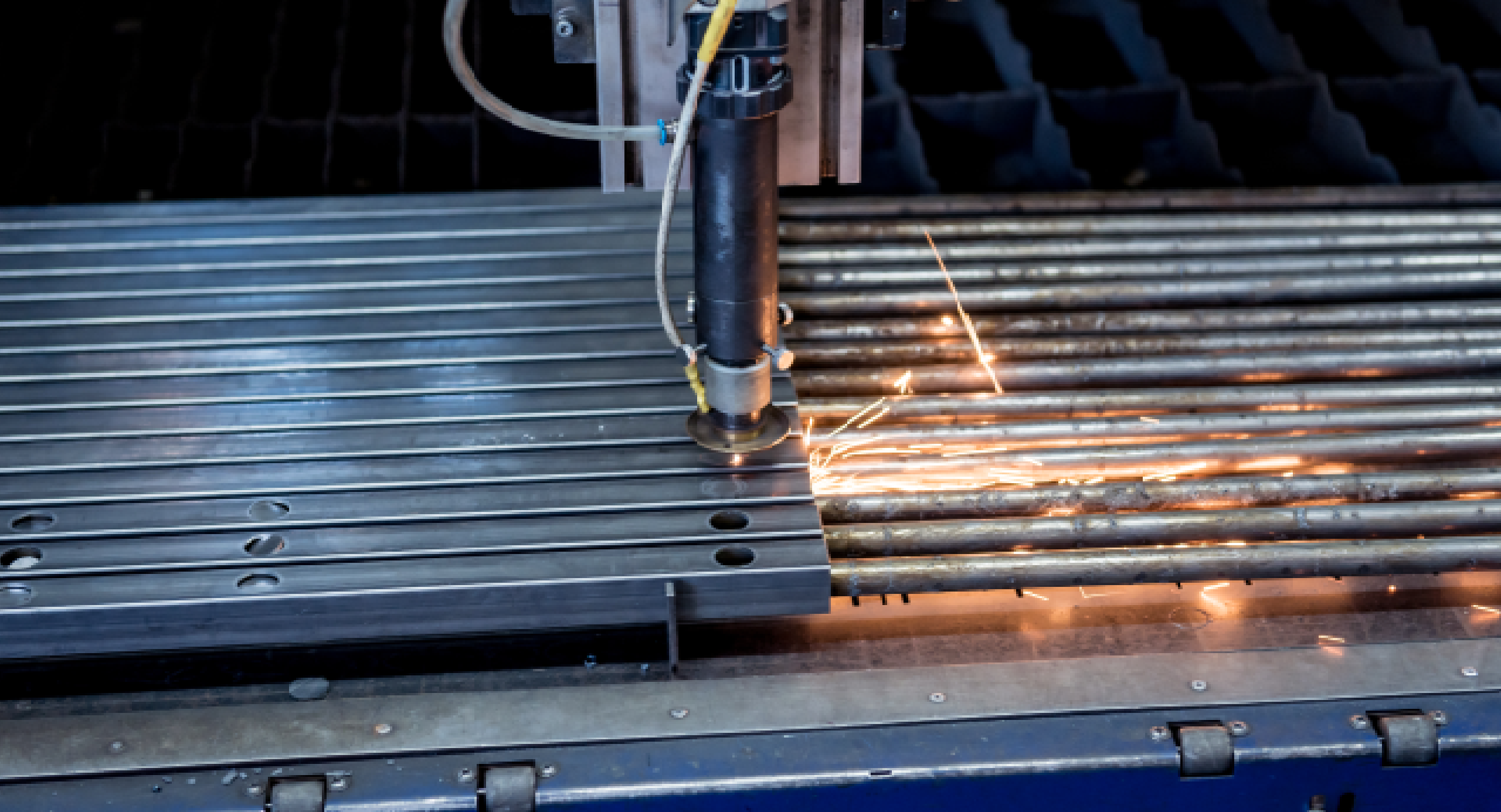

In high-performance manufacturing, the quality of the joint determines the final product’s reliability, safety, and longevity. Traditional methods like TIG and MIG welding, while versatile, introduce significant heat and distortion, often requiring extensive post-weld processing. The metal laser welding machine overcomes these drawbacks by delivering a highly focused energy beam that creates deep, narrow welds with minimal heat-affected zones (HAZ). This non-contact process enables higher processing speeds, drastically reducing cycle times and minimizing material deformation. Consequently, high-power laser welding equipment has become indispensable for critical applications where structural integrity and minimal distortion are non-negotiable requirements, establishing a new benchmark for industrial joining processes.

The Fiber Laser Welding Machine: Power and Efficiency

The most widely adopted core technology in the industrial sector is the fiber laser welding machine, renowned for its superior beam quality and exceptional wall-plug efficiency. Fiber lasers utilize solid-state gain media and deliver the beam through a flexible optical fiber, providing high stability and requiring significantly less maintenance than older CO2 or Nd:YAG lasers. This efficiency translates directly into lower operational costs and a superior return on investment over the machine’s lifespan. Its short wavelength is readily absorbed by highly reflective materials like copper and aluminum, making the fiber laser welding machine the optimal choice for demanding applications, including electric vehicle battery assembly and specialized aerospace components.

Laser Beam Delivery Systems

Dynotech specializes in supplying high-precision laser beam delivery systems, which are essential laser welding equipment for industrial integration. These modular systems—comprising mirrors, collimators, and focusing heads—safely and accurately guide the laser beam from the welding machine laser source to the workpiece. Proper beam delivery ensures minimal energy loss and maintains the quality and intensity of the laser focus spot, which is critical for achieving consistent weld depth and profile, whether in an automated robotic cell or a flexible handheld configuration.

Applications of Laser Machine Welding

The flexibility of a modern laser machine welding system allows for a vast array of joining applications across diverse industries. From spot welding small electronic components to continuous seam welding in heavy plate fabrication, the laser’s power and focus can be finely tuned to the specific requirement. Key applications include hermetic sealing for medical devices, joining dissimilar metals with high precision, and high-speed butt welding in automotive body-in-white structures. The sheer versatility of the metal laser welding machine makes it a central component in any manufacturing environment prioritizing high throughput and rigorous quality control for complex, high-value components.

Metal Cutting and Welding Systems (Penta Laser)

Through our partnership with global leader Penta Laser, Dynotech offers integrated systems that combine the capabilities of a dedicated metal laser welding machine with high-power cutting functionality. These robust laser welding equipment solutions are designed for industrial scale, offering a power range up to 60KW and custom configurations for both cutting and welding applications. This integration provides maximum utility and flexibility, allowing manufacturers to use a single high-value asset for both intricate 3D cutting and high-speed metal joining, optimizing floor space and capital investment.

Laser Welding Machine Portable: Agility in Fabrication

While fixed systems dominate automated lines, the flexibility offered by a laser welding machine portable unit has revolutionized custom fabrication. These compact units bring the high-quality benefits of laser machine welding directly to the workpiece, eliminating the need to fixture and move large, heavy components. This portability is invaluable for on-site repairs, custom job shops, and applications where the geometry of the part makes fixed automation impractical. Despite their smaller footprint, these units retain the precision and low heat input necessary to produce superior welds on materials like thin stainless steel, often replacing slower, more cumbersome TIG welding processes entirely.

Maximizing Utility: The Laser Cutting Welding Machine

A compelling case for investment exists in multi-functional systems, particularly the laser cutting welding machine, which maximizes resource efficiency. By integrating both cutting and welding capabilities into a single system with dynamic tool-changing capabilities, manufacturers can drastically reduce capital expenditure and floor space requirements. This versatility is highly attractive for fabrication shops that handle diverse tasks, allowing for rapid changeover from complex profile cutting to high-speed welding. The dual functionality ensures that the specialized metal laser welding machine component of the system provides utility even when there are no joining tasks in the queue, thereby maximizing the asset’s uptime and profitability.

Investment and Operational Advantages

The operational advantages of laser technology strongly influence the total cost of ownership (TCO) compared to traditional welding machine laser alternatives. Although the initial investment in laser welding equipment is higher than conventional welders, the long-term savings are significant. Laser systems virtually eliminate the need for costly consumables (wire, nozzles, etc.), drastically reduce labor costs due to higher speed and minimal post-processing, and cut down on material waste through minimal HAZ and distortion. Furthermore, the inherent reliability of the fiber laser welding machine translates into less downtime and higher production consistency, ensuring a rapid return on investment.

Ensuring Weld Integrity and Quality Control

A critical operational requirement for all laser machine welding is the implementation of robust quality control protocols. Modern systems employ advanced sensors and vision systems to monitor the weld process in real-time, ensuring consistency in depth, width, and profile. This allows manufacturers to maintain the high standards required by industries like aerospace and medical devices. The data collected by the metal laser welding machine provides full traceability for every joint, offering verifiable proof of compliance and quality, a non-negotiable feature for high-reliability components.

Dynotech’s Expertise in Advanced Fabrication

Dynotech Instruments Pvt. Ltd. is committed to elevating the quality and efficiency of Indian industrial fabrication. By partnering with global technology leaders like Penta Laser, we provide the full spectrum of advanced laser welding equipment solutions, from high-power automated systems to agile laser welding machine portable units.

Partnering for Manufacturing Excellence in India

We ensure that our clients receive the best-in-class fiber laser welding machine systems, backed by expert application engineering and reliable local support. Dynotech helps manufacturers transition confidently to the efficiency of laser technology, providing the welding machine laser solutions and expertise required to achieve world-class precision and throughput in the competitive global market.

FAQs

What makes the fiber laser welding machine the preferred source for high-volume industrial welding equipment?

The fiber laser welding machine is preferred because of its superior beam quality and high electrical efficiency, which directly translate to operational benefits. The fiber laser source generates a highly focused beam, allowing for deep, narrow welds at very high speeds. Its high wall-plug efficiency reduces power consumption and heat generation compared to older laser sources. Furthermore, the robust, solid-state design results in a virtually maintenance-free welding machine laser with minimal downtime, making it the most cost-effective and reliable choice for high-volume laser machine welding applications.

How does the use of laser welding equipment minimize material distortion in sensitive metal components?

laser welding equipment minimizes material distortion by drastically reducing the heat input into the material. The highly concentrated energy beam, characteristic of a metal laser welding machine, focuses the heat precisely on the joint line, creating a deep weld rapidly. This short interaction time and localized heating create a very small Heat Affected Zone (HAZ). By limiting the area and duration of heating, the system prevents the expansion and contraction that causes warping and distortion, a major advantage over traditional methods for thin metals or complex assemblies.

In which manufacturing scenarios is a laser welding machine portable system most beneficial?

A laser welding machine portable system is most beneficial in custom fabrication shops, repair environments, and manufacturing scenarios where the workpiece is large, heavy, or otherwise difficult to move. The flexibility of a laser welding machine portable system allows the operator to bring the high-precision laser gun directly to the component, eliminating the labor and logistical challenges associated with fixturing and moving large objects. It is also an excellent entry-level option, providing the quality of laser machine welding at a lower initial investment than a fixed, automated cell.

What are the advantages of investing in a multi-functional laser cutting welding machine system?

The primary advantage of investing in a multi-functional laser cutting welding machine is maximized asset utility and reduced capital expenditure. A single machine can perform both complex 3D cutting and high-speed precision welding, saving the cost and floor space required for two separate systems. This versatility makes the asset highly valuable in fabrication shops with diverse requirements, allowing for rapid changeovers between tasks. It ensures the metal laser welding machine component is productive even during non-welding periods, maximizing efficiency and providing a competitive edge.

How does the laser welding machine portable system justify the welding laser machine price over traditional welders?

The portable system justifies the welding laser machine price through superior quality, speed, and reduced operational costs. The high-speed process and high-quality, clean welds drastically reduce labor time, especially the time spent on post-weld grinding and finishing, a major expense in arc welding. Furthermore, the system requires minimal consumables compared to traditional welders. These operational efficiencies, combined with the superior quality delivered by the fiber laser welding machine technology, ensure a quick return on investment, making the seemingly higher initial price ultimately more economical in the long run.