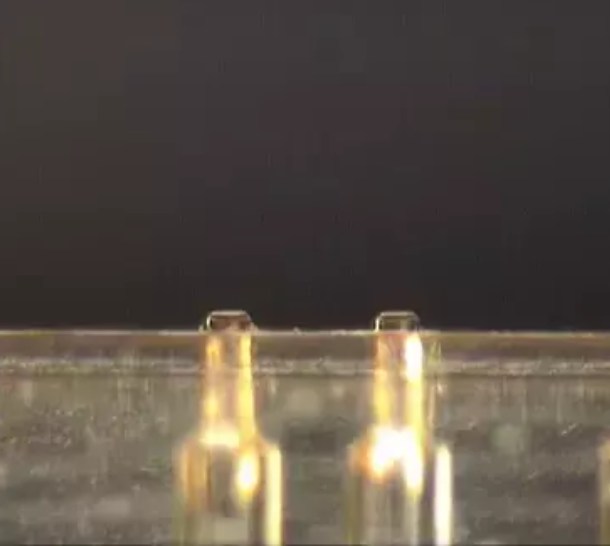

Laser cleaving uses precision laser technology to accurately and precisely terminate optical fibers, with flat or angled facets on a broad range of fiber types and waveguides. We work closely with OpTek Systems, which offers customers the ability to develop custom advanced sensors for critical environments at micron precision and scalable production speeds. The Laser cleaving technology's flexibility means that the end face's geometry can be adjusted to suit the application. Laser cleaving delivers superior optical quality compared to mechanical termination. It can be applied to free fibers, fiber ribbons and arrays, optical connectors, and even in-situ packaged fibers and waveguides.

Laser cleaving uses precision laser technology to accurately and precisely terminate optical fibers, with flat or angled facets on a broad range of fiber types and waveguides.

Laser cleaving delivers superior optical quality compared to mechanical termination. It can be applied to free fibers, fiber ribbons and arrays, optical connectors, and even in-situ packaged fibers and waveguides.

Initially used by broadband optical telecommunications, today, laser cleaving is delivering its performance advantages to optical fibers used in various industries such as telecoms, datacoms, fiber lasers, biomedical, oil and gas, and a range of sensing applications.

Copyright 2022 Dynotech. Designed & Developed By Conceptualise